News

Gaotian Pump Company's intelligent water supply pump room project was successfully implemented, leading a new trend in water management.

Gaotian Pump Company's intelligent water supply pump room project was successfully implemented, leading a new trend in water management.

The installation and construction of the prefabricated pump station project of Gaotian Pump Company is progressing smoothly

In the realm of disaster response, especially when dealing with emergencies such as floods and landslides, efficient drainage systems are indispensable. High lift pumps serve as crucial equipment in these scenarios, enabling rapid elevation of water levels and providing timely aid. This article will introduce several types of high lift pumps commonly used in disaster response and explore their characteristics and applications.

When conventional centrifugal pumps fail to meet the requirements for handling viscous fluids, gear pumps step in as efficient solutions. These pumps leverage the interlocking action of gears to propel the fluid through the system. Known for their simplicity and reliability, gear pumps are particularly useful in applications involving oils and certain chemicals. Their ability to handle materials with particulates and their straightforward operation make them a practical choice. However, users should be cautious of the potential heat buildup during the pumping of highly viscous liquids, necessitating careful management of the pump's operational parameters to prevent overheating.

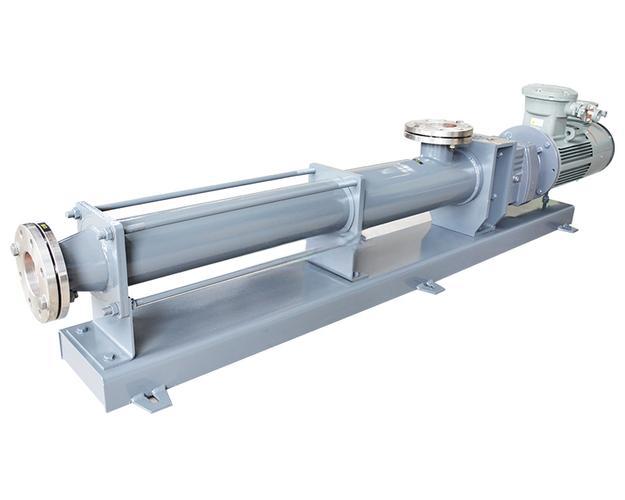

Working Principle of Sludge Screw Pumps

The sludge screw pump is a single-screw positive displacement pump. Its principle involves the rotation of an eccentric single-spiral screw within a double-spiral liner, which pushes thick slurry along the spiral groove from the suction inlet to the discharge outlet, thereby achieving the pump's conveying function. Below is a detailed introduction to the principle and performance of the sludge screw pump.

Water pumps are essential for ensuring a reliable supply of drinking water in households, communities, and industrial settings. The lifespan of these pumps varies significantly based on multiple factors, but with optimal conditions and maintenance, they can serve efficiently for many years. This article explores the typical lifespan of water pumps used for drinking water, the factors influencing their durability, and strategies to maximize their operational life.

Energy-saving methods for motor use in pumping systems are crucial considerations in both production and daily operations. Below, technical experts from Shanghai Gaotian outline various strategies for optimizing energy efficiency during motor operation in pumping systems:

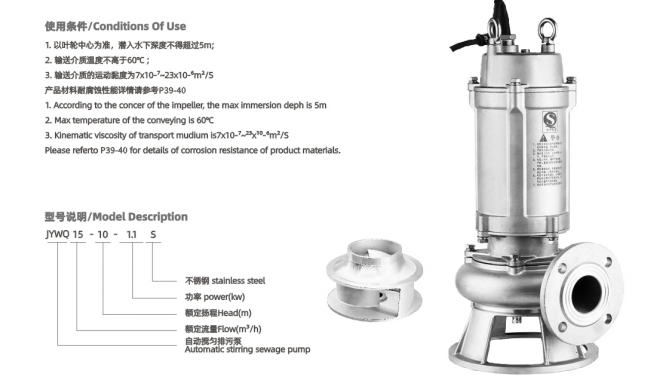

How to choose a sewage pump

Purchasing a sewage pump requires careful consideration to ensure efficient and reliable operation. Here are nine key factors to evaluate when choosing a sewage pump: Flow Rate: The flow rate indicates the amount of water the pump can discharge per hour. Choose one that matches your specific needs, such as 5-10 m³/h for a standard home setup with minimal plumbing. Larger homes or those with additional appliances like washing machines might need a pump with higher flow rates. Installing a dual-pump system can also be beneficial in certain situations.

The main energy-saving technologies for pumps are discussed here, primarily focusing on their applications and limitations. The four methods highlighted include: 1. Cutting the Impeller 2. Variable Frequency Drive (VFD) Technology 3. Ternary Flow Technology 4. Specialized Energy-Efficient Pumps

In the complex landscape of wastewater management, cast iron sewage pumps consistently emerge as the default solution for myriad residential, commercial, industrial, and municipal applications. This article examines the engineering, material, and operational factors driving their unparalleled versatility across global drainage scenarios.

How Diesel Generators Power the World

Diesel generators remain vital energy sources for industries, emergency backup systems, and remote operations due to their reliability and efficiency. Understanding their working principles involves exploring both the diesel engine and the electricity generation process. Here’s a comprehensive look at how diesel generators convert fuel into electrical energy.