Multistage Water Suply Pump

- Gaotian

- Shanghai

- 15days

- 1500

Multistage Water Suply Pump is a unit composed of multiple levels of water pumps, with each pump stage connected to the others. Because each pump is responsible for different pressures, the entire multistage pump can generate high pressure. Compared to traditional single-stage pumps, multistage pumps have a more compact structure and lighter weight, significantly reducing the footprint and making installation and maintenance more convenient.

Multistage pumps are made up of multiple small pumps, each with its axis aligned and mounted on the same motor, allowing for more pump stages to be stacked in a smaller space, thus achieving higher flow rates and greater pressure. In addition, multistage pumps typically employ advanced fluid dynamics design techniques, resulting in smoother water flow and more uniform speed, to achieve higher performance and efficiency.

A Multistage Water Suply Pump is a type of pump that connects multiple pump stages to work together, and it has the following characteristics:

1. High head: A Multistage Water Suply Pump is composed of multiple pump stages, and each stage can increase a certain head, so the total head of a multistage pump can reach a high level. This makes multistage pumps very suitable for situations where water flow needs to be transported to higher places, such as water supply systems in high-rise buildings, and industrial conveying systems.

2. Large flow rate: Each pump stage of a multistage pump can increase a certain flow rate, so the total flow rate of a multistage pump can reach a high level. This makes multistage pumps very suitable for situations that require high flow rates, such as cooling systems and water supply systems in industrial production.

3. High efficiency: Each pump stage of a multistage pump can increase a certain head and flow rate, so the overall efficiency of a multistage pump is relatively high. This is because multistage pumps can fully utilize the input energy and reduce energy loss. High-efficiency multistage pumps can save energy and reduce operating costs.

4. Good stability: A multistage pump is composed of multiple pump stages, and each stage can balance a portion of the pressure and flow rate, so the operation of a multistage pump is more stable. Even if one pump stage fails, the other stages can continue to work, ensuring the normal operation of the system.

5. Compact structure: The pump stages of a multistage pump typically use an axially segmented structure, making the overall pump compact and occupying a small footprint. This makes multistage pumps very suitable for situations with limited space, such as ships and aviation.

6. High reliability: Each pump stage of a multistage pump can balance a portion of the pressure and flow rate, making the overall pump operation more stable and reliable. Multistage pumps typically use high-quality materials and advanced manufacturing processes, increasing the pump's durability and reliability.

7. Convenient maintenance: Each pump stage of a multistage pump can be disassembled and repaired separately without affecting the operation of other stages. This makes the maintenance of multistage pumps more convenient and efficient, reducing downtime and maintenance costs.

Multistage Water Suply Pump application

Water Supply:Water plant filtration and transmission, zoned water supply from water plants, mainline boosting, high-rise building boosting.

Industrial Boosting:Process water systems, cleaning systems, high-pressure washing systems, fire-fighting systems.

Industrial Liquid Conveyance:Cooling and air conditioning systems, boiler feedwater and condensation systems, machine tool support, conveyance of acidic and alkaline mediums.

Water Treatment:Ultrafiltration systems, reverse osmosis systems, distillation systems, separators, and swimming pool water treatment systems.

Irrigation:Farmland irrigation, sprinkler irrigation, drip irrigation.

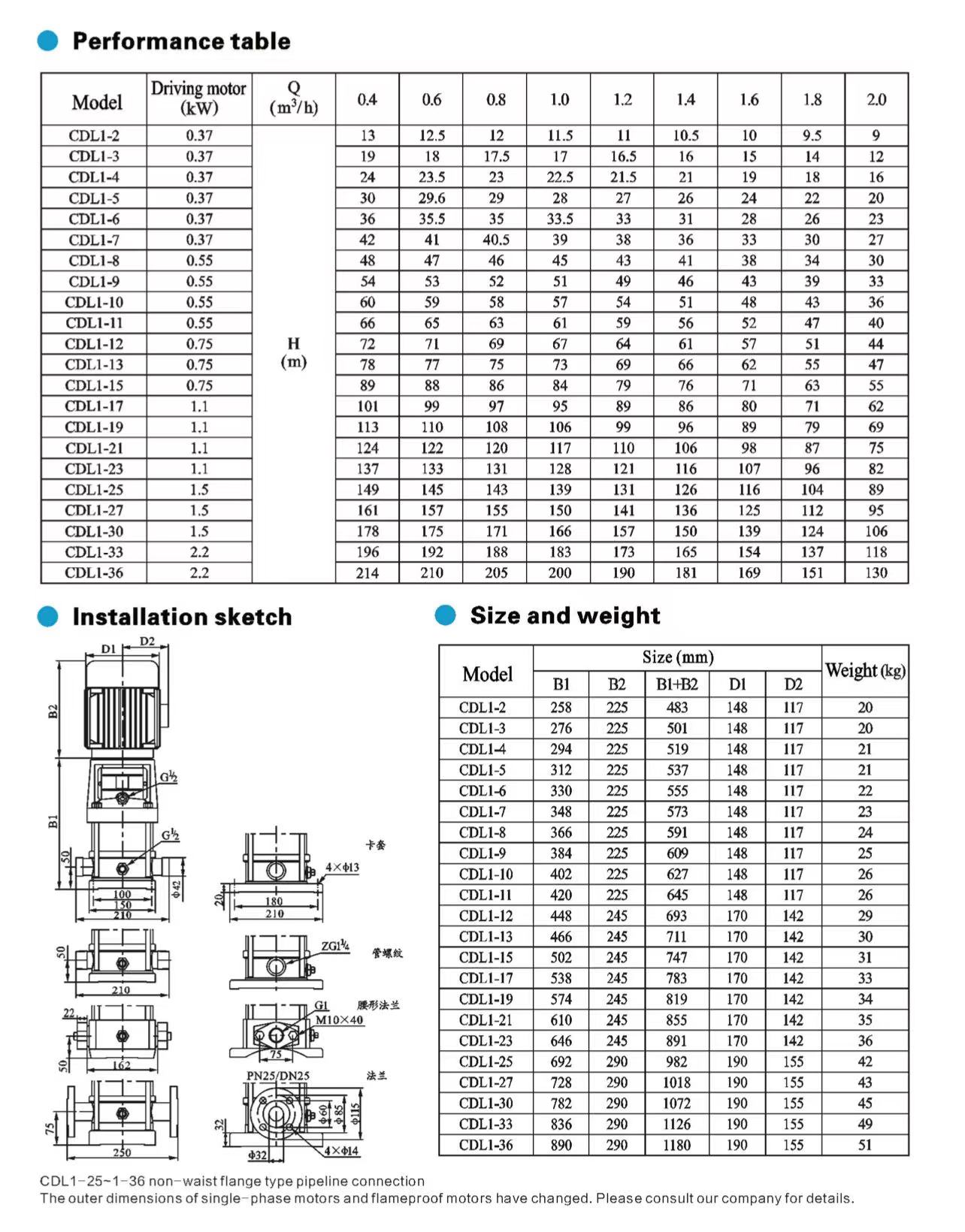

Multistage Water Suply Pump performance and structure