Diaphragm Pump

As a leading name in diaphragm pump technology, Gaotian prides itself on a string of prestigious certifications. Our expertise lies in crafting top-notch diaphragm pumps that deliver both durability and efficiency, specifically tailored for rigorous industrial environments. Emphasizing on meticulous design, Gaotian 's pumps showcase unparalleled performance and steadfast reliability. Backed by meticulous testing and stringent industry recognition, our diverse portfolio is built to meet the unique demands of different industries, ensuring seamless fluid handling and extended operational life. Entrust Gaotian to be your partner in harnessing the engineering prowess behind efficient and durable diaphragm pump solutions.

-

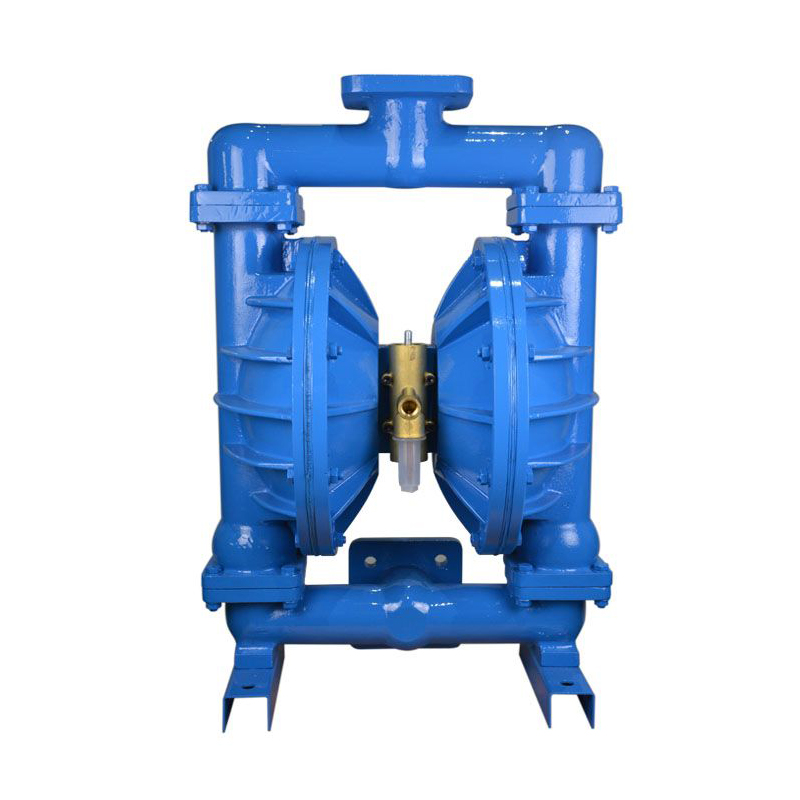

Pnemetic Aluminium Double Diaphragm Pump

Pnemetic Aluminium Double Diaphragm Pump is precision-cast, with a smooth and tidy surface, and possesses higher strength. The diaphragm connecting rod is made of wear-resistant stainless steel, providing better corrosion resistance and a longer lifespan. PP, aluminum alloy, and stainless steel intermediate bodies are available.

Email Details -

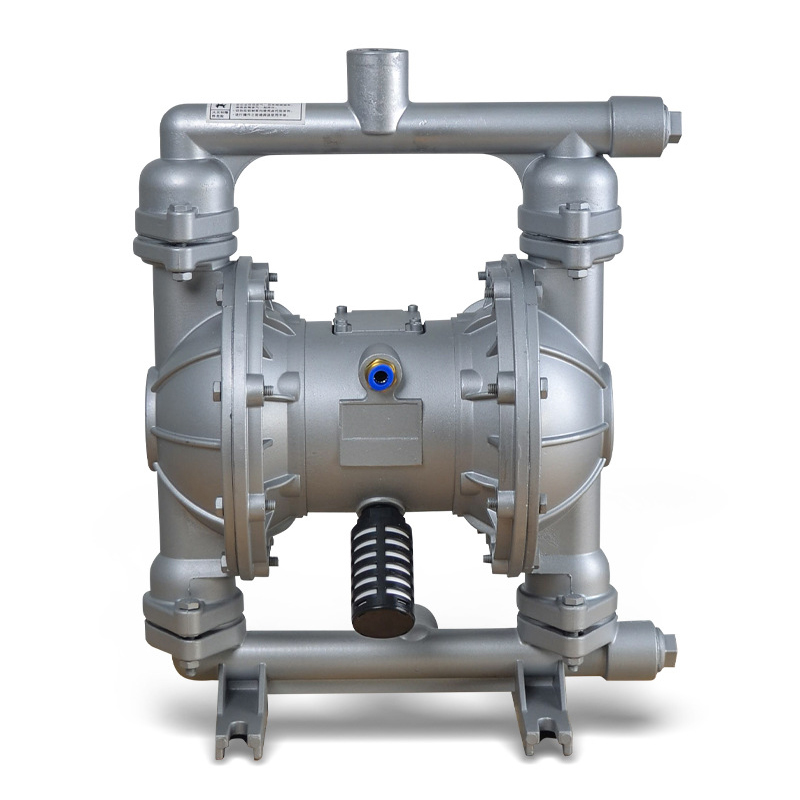

Stainless Steel Diaphragm Pump

Stainless Steel Diaphragm Pump is an improvement based on the QBY pneumatic diaphragm pump, incorporating an internal air distribution valve. With a simpler structure, increased flow rate, and higher lift, it offers stable performance. It combines the advantages of self-priming pumps, submersible pumps, shielded pumps, slurry pumps, and impurity pumps. Widely used in industries such as chemical, petroleum, pharmaceutical, mining, papermaking, cement plants, steel plants, power plants, and coal processing industries.

Email Details -

Air Driven Diaphragm Pump

Performance Advantages of Air Driven Diaphragm Pump:

Email Details

1. Flow + Pulsation and Gas Consumption = Performance

2. Bolted Construction and Wide Material Selection

3. Modular Structure for Easy Maintenance

4. Spark-Free and Heatless Operation

5. User-Friendly Operation

6. Low Shear Force on Materials:

7. Patented Air Valve Design for Reliability -

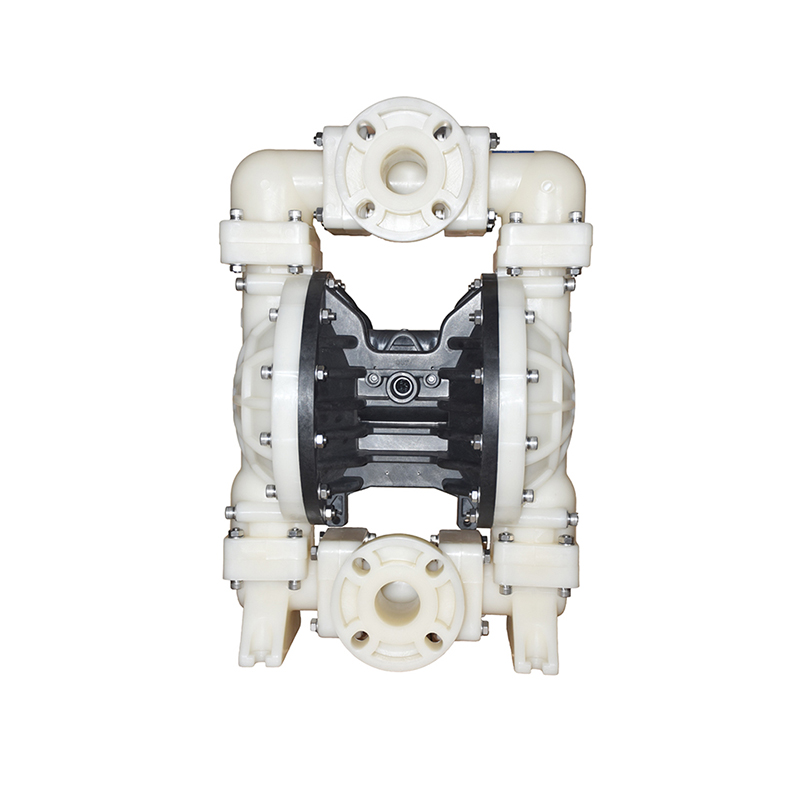

Plastic Chemical Diaphragm Pump

The features of a Plastic Chemical Diaphragm Pump may include:

Email Details

1. Corrosion Resistance: Designed to handle chemicals, these pumps are typically constructed from high-performance plastic materials, offering excellent corrosion resistance. They can safely and reliably transport various corrosive media such as acids, alkalis, solvents, etc.

2. Energy Efficiency and Environmental Friendliness: Compared to traditional pump technologies, plastic chemical diaphragm pumps often utilize pneumatic drives, eliminating the need for electricity and thus promoting energy efficiency and environmental friendliness. Additionally, their sealed design effectively prevents leaks, reducing chemical volatilization and environmental pollution.

3. High Reliability: These pumps feature a simple yet stable structure, requiring no additional lubrication, thus reducing maintenance costs and downtime. With a dual-diaphragm design, they ensure the stability and safety of fluid transportation. Even if one side fails, the other side can continue working, ensuring continuous production processes.

4. Wide Applicability: Due to their superior material selection and structural design, plastic chemical diaphragm pumps are suitable for various industries and applications, including chemical, petroleum, pharmaceutical, food processing, etc. They fulfill the requirements of different media transportation needs. -

3 Inch Electric Diaphragm Pump

● Precision casting with smooth and tidy surface, and higher strength. The valve ball is further processed by a special machine for high roundness and good sealing performance.

Email Details

● Precisely calculated diaphragm movement distance, reducing diaphragm stress and extending service life.

● Four-bolt connection design for good sealing performance, with actual dry suction of 4-7 meters. Three-stage upper and lower covers for flexible and convenient installation.

● Integral design of diaphragm guard block with excellent pressure resistance and high-temperature performance, widely used in the compressor industry. -

Acid Resistance Airpowered Transfer Pump

Acid Resistance Airpowered Transfer Pump technical parameters

Email Details

Maximum particle diameter: 6 mm

● Maximum flow rate: 587 L/min

● Maximum head: 84 m

● Maximum air supply pressure: 8.4 bar

● Self-priming head: 0-8 m

● Inlet/outlet port: 2 in

Materials

● Pump body: Polypropylene, Polyoxymethylene (POM), PVDF, PTFE

● Diaphragm: Santoprene rubber, Polyether rubber, Fluororubber, PTFE, EPDM, Nitrile rubber

● Valve ball: PTFE, Stainless steel, Santoprene rubber, Polyether rubber, Fluororubber, Ceramic

● Valve seat: PTFE, Santoprene rubber, Polyether rubber, Fluororubber, Polypropylene -

QBK All Plastic Diaphragm Pump

The QBK diaphragm air pump has eight common specifications with diameters of: 10mm (3/8"), 015mm (1/2"), 025mm (1"), 040mm (1/2"), 50mm (2"), 65mm (2 1/2"), 80mm (3"), 100mm (4"). It comes in three materials: aluminum alloy, cast iron, stainless steel. Diaphragm pumps are equipped with different diaphragm materials including nitrile rubber, chloroprene rubber, fluorine rubber, and polytetrafluoroethylene, to meet the needs of different users according to different liquid media.

Email Details

Since its inception, this pump has been adopted by many units in petroleum, chemical, electronic, ceramic, and textile systems, placed in various special occasions to pump various media that conventional pumps cannot handle, and has achieved satisfactory results. -

Diaphragm Air Pump

Diaphragm Air Pump is a new type of conveying machinery that can transport various corrosive liquids, liquids with particles, high viscosity, volatile, flammable, and highly toxic liquids.

Email Details

In the painting and ceramic industries, Diaphragm Air Pump have already taken a leading position, while in other industries such as environmental protection, wastewater treatment, construction, sewage discharge, and fine chemicals, they are expanding their market share and have an irreplaceable position that other pumps cannot fulfill. -

Air Operated Double Diaphragm Pump

Product Features of Air Operated Double Diaphragm Pump:

Email Details

● Air-driven diaphragm design allows for handling liquids with solid particles and high viscosity.

● Air-driven operation is suitable for use in high-risk environments.

● Anti-stalling air valve reduces pump downtime, freezing, and lubricant use issues.

● When using Teflon diaphragms, the flow rate decreases by 20%, and the self-priming height decreases to 10 feet (dry) or 20 feet (wet).