Stainless Steel Precision CastingSmall Submersible Electric Pump

- Gaotian

- Shanghai

- 15days

- 1500

1. WQ(D)-S Series sewage pump is made of stainless steel shell precision casting. it's corrosion-resistant, environmentally friendly, beautiful appearance, small size and durable.

2. Using fluorine rubber seal double end face and fluorine rubber radial seal, effectively preventcontaminated water infittration on conditions of liquid seal protection.

3. Motor with F class insulation, equipped with thermal protection device, long service life.

Stainless Steel Submersible Pump description

The Stainless Steel Submersible Pump , constructed with a precision-cast stainless steel shell, offers a versatile solution for various sewage handling applications. Its robust design, coupled with advanced features, ensures efficient performance and long-term reliability in challenging environments.

Firstly, the corrosion-resistant stainless steel construction makes it ideal for use in sewage systems where durability and resistance to harsh chemicals are paramount. Whether in municipal wastewater treatment plants or industrial facilities, this pump can withstand corrosive elements, ensuring uninterrupted operation and minimal maintenance requirements.

Secondly, the incorporation of fluorine rubber seals, both in double-end face and radial configurations, provides superior protection against water ingress and contamination. This feature is crucial for maintaining the integrity of the pumping system, especially in environments with high levels of pollutants or corrosive substances.

Moreover, the Stainless Steel Submersible Pump is equipped with a motor featuring F class insulation and a thermal protection device. This ensures safe and reliable operation even under demanding conditions, extending the service life of the pump and reducing the risk of overheating or electrical malfunctions.

In conclusion, the Stainless Steel Submersible Pump is well-suited for a wide range of applications, including but not limited to municipal sewage treatment plants, industrial wastewater management, and commercial facilities. Its combination of corrosion resistance, advanced sealing technology, and robust motor design makes it a dependable choice for handling sewage and other challenging fluids effectively.

Stainless Steel Submersible Pump working conditions

1. The medium temperature should not exceed 80°C, with a density ranging from 1.0 to 1.3 kg/m³. The use of 304 stainless steel is recommended within a pH range of 4 to 10; however, for mediums beyond this range, it is advisable to utilize 316 stainless steel.

2. Generally, the pump must operate within the specified head range to ensure the motor is not overloaded. If operation within the entire head range is necessary, it should be specified at the time of ordering.

3. During operation, the motor current must not exceed the rated current of the motor.

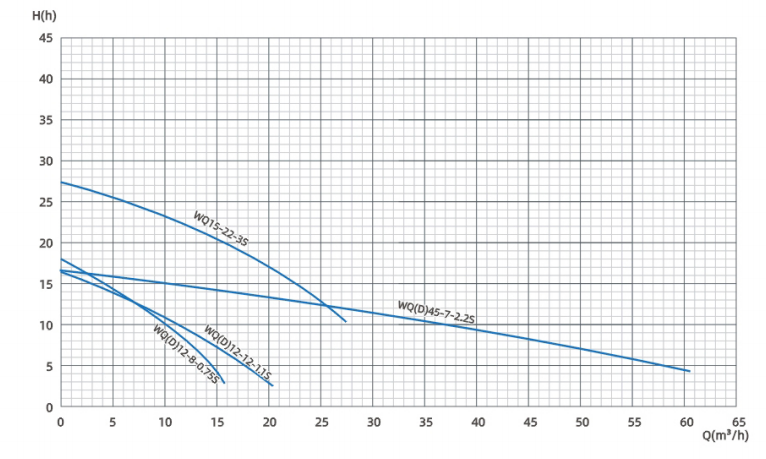

Performance Curve