Adjustment and use of pipeline centrifugal pump

1. Starting of pipeline centrifugal pump

(1) Before starting the pipeline centrifugal pump, the pump rotor should be rotated to check whether the rotor is flexible;

(2) Check whether the motor rotation direction is consistent with the pump rotation direction;

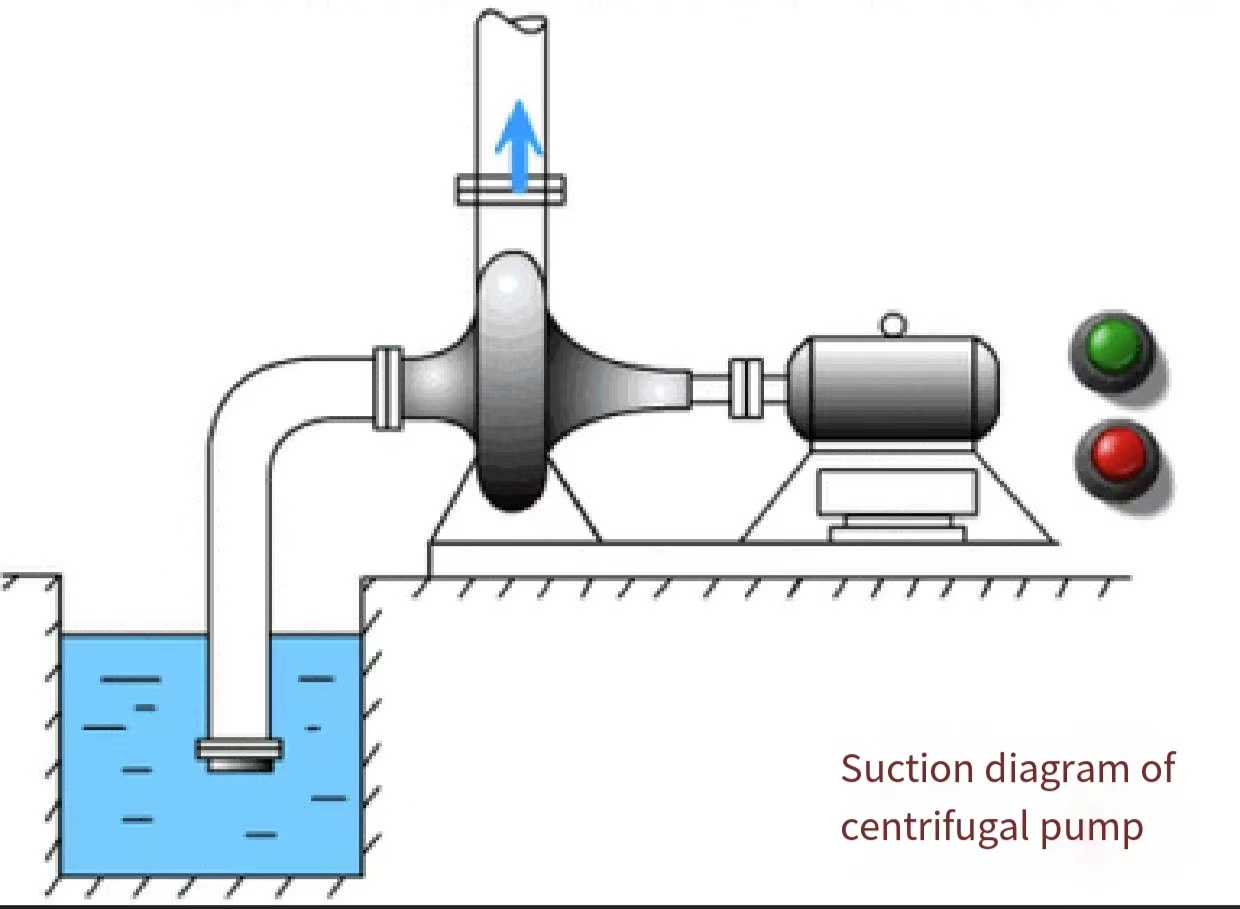

(3) Open the suction valve of the pump (if a suction valve is installed), close the gate valve of the pump outlet pipeline and the pressure gauge cock, so that the pump is filled with liquid, or use this system to eliminate the air in the suction pipeline and pump;

(4) Check the tightness of the connecting bolts between the pump and the motor and the safety conditions around the pump, so that the pump is ready to start;

(5) Start the motor, wait until the pump operates normally, open the pressure gauge cock, and slowly open the pump outlet gate valve until the pressure gauge pointer points to the required pressure (control the pump's given lift according to the outlet pressure gauge reading).

2. Operation of pipeline centrifugal pump

(1) The pipeline centrifugal pump relies on the balancing mechanism in the pump to balance the axial force. The balancing liquid flows out of the balancing device. The balancing liquid is connected to the water inlet section through the balancing water pipe, or a short pipe is designed outside the balancing room. The balancing liquid flows through the short pipe. The pipe flows out of the pump. To ensure the normal operation of the pump, the balance water pipe is not allowed to be blocked.

(2) During startup and operation, attention must be paid to observing instrument readings, bearing temperature, packing leakage and temperature, and pump vibration and sound to see if they are normal. If any abnormalities are found, they should be dealt with in a timely manner;

(3) The change in bearing temperature rise reflects the assembly quality of the pump. The bearing temperature rise shall not be higher than the ambient temperature by 35°C, and the bearing temperature shall not be higher than 75°C;

(4) There is a certain amount of axial movement in the pump rotor during operation. The axial movement should be within the allowable range, and the gap value between the end faces of the two half couplings of the motor and water pump should be ensured;

(5) During the service period of the pump, the wear of the impeller, sealing ring, guide vane sleeve, shaft sleeve, balance plate and other parts should be checked regularly; if the wear is excessive, it should be replaced in time.

3. Shutdown of pipeline centrifugal pump

(1) Before stopping the pipeline pump, you should first close the cock of the pressure gauge, slowly close the outlet gate valve, and then close the suction valve of the pump (if a suction valve is installed) after the pipeline pump stops;

(2) If the pipeline pump is out of service for a long time, all drain cocks under the water inlet section, middle section, and outlet section of the pump should be removed, the remaining water should be drained, and the pump should be disassembled, cleaned, oiled, and packaged for storage.