Advantages and applications of low viscosity melt gear pumps

As an efficient power transmission equipment, low viscosity melt gear pump has shown significant advantages and broad application prospects in many industrial fields. The following is a detailed analysis of its advantages and applications:

1. Advantages

Design optimization: Low viscosity melt gear pumps usually adopt streamlined optimization design, which effectively reduces the resistance of the fluid in the pump and reduces energy consumption. This design also ensures the self-cleaning ability inside the pump body, avoiding performance degradation or increase in maintenance costs caused by material residue.

Intelligent control: Many modern low-viscosity melt gear pumps have introduced intelligent control systems, which can automatically adjust operating parameters, such as rotation speed, temperature, etc., according to real-time working conditions. This not only protects the material quality, but also extends the service life of the pump, and brings a more convenient and efficient operating experience to users.

Wide applicability: The low viscosity melt gear pump can adapt to materials with different viscosity ranges, from low viscosity chemical materials to high viscosity rubber. In addition, they can adapt to normal and high temperature conditions, showing strong adaptability.

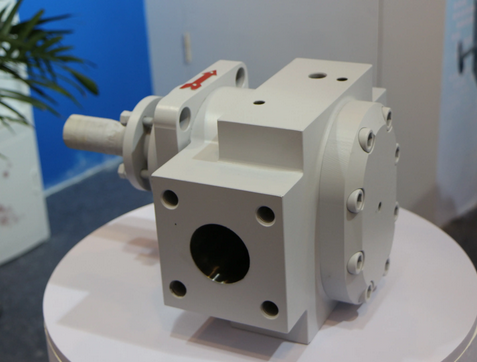

High precision: The melt gear pump has a precise structure and high precision, which can ensure the stability and accuracy of materials during transportation. This is crucial to improving product quality and production efficiency.

Customized services: For special industries or high-demand application scenarios, low viscosity melt gear pumps can provide customized services. According to the specific needs of customers, the size, material, sealing form, etc. of the pump are adjusted to ensure that each pump can accurately meet the individual needs of customers.

2.Application

Plastic processing industry: Low viscosity melt gear pumps are particularly widely used in the plastic processing industry. They can be installed between the extruder outlet and the machine head, and play a key role in the extrusion molding process of polymers such as granulation, film, pipe, plate, and sheet. By providing stable melt delivery and precise flow control, it helps improve product molding quality and production efficiency.

Chemical fiber and resin industry: The materials in these industries usually have lower viscosity and larger flow rate, and low viscosity melt gear pumps can well meet these needs. They are widely used in the transportation and pressurization process of chemical fiber, resin and other materials.

Petroleum, chemical and pharmaceutical industries: In these industries, low viscosity melt gear pumps can be used for material transportation in various chemical processes. Its precise flow control and stable conveying performance help improve product quality and production efficiency.

Environmental protection field: With the increasing environmental protection requirements, the application of environmentally friendly materials such as biodegradable plastics has become increasingly widespread. Low viscosity melt gear pumps play an important role in the transportation and processing of these materials, helping to promote the development of the environmental protection industry.