Application range of asphalt gear pump

Asphalt gear pumps have a wide range of applications, mainly reflected in the following aspects:

1. Industry application

Asphalt gear pumps are widely used in various industries such as petroleum, chemical fiber, metallurgy, machinery, electricity, machine tools, ships, glass, and highways. Especially in construction projects such as roads and squares, asphalt gear pumps are important equipment for asphalt (residual oil) spraying operations.

2. Medium transportation

High-temperature viscous liquid: Asphalt gear pumps are mainly used for suction, transportation and spraying of high-temperature asphalt (residual oil) liquids, which can maintain the appropriate temperature of asphalt during transportation to ensure smooth construction.

Non-high volatility, low flash point petroleum products: At room temperature, asphalt gear pumps can also be used to suction and transport non-high volatility, low flash point petroleum products, such as various motor oils, mechanical oils and heavy oils.

3. Specific occasions

Outdoor installation in high-cold areas: Since asphalt gear pumps have insulation function, they are particularly suitable for outdoor installation in high-cold areas and occasions where insulation is required during the process.

Occasions requiring heat preservation during the process: For media that are solidified at room temperature, asphalt gear pumps can heat and insulate by passing through heating media such as heat transfer oil, hot water, and steam to ensure that the medium maintains a suitable temperature and fluidity during transportation.

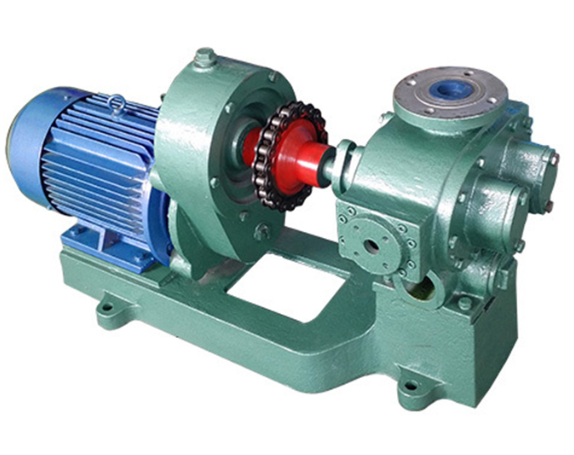

IV. Performance characteristics

Structural characteristics: The main flow-through parts of the asphalt gear pump are equipped with hollow interlayers, which can pass through heating media such as steam, hot water, and heat transfer oil to heat and insulate the conveying liquid and pump. At the same time, according to the viscosity and transportation requirements of asphalt, transmission methods such as reducers, speed-regulating motors or pulleys can be used to reduce the speed of the pump and improve the transportation capacity.

Material and life: Asphalt gear pumps are usually made of cast steel, which has a long service life, more than 5 times that of cast iron. Its Class II material Q235 is suitable for conveying non-corrosive, solid-free heavy oil, asphalt and other media below 350°C.

In summary, asphalt gear pumps play an important role in many industries such as petroleum, chemical industry, and construction with their wide range of applications, excellent transportation performance and reliable material guarantee.

To learn more, please visit:

https://youtube.com/@gt-pump?si=gYw_o3qyY4rm5mCX