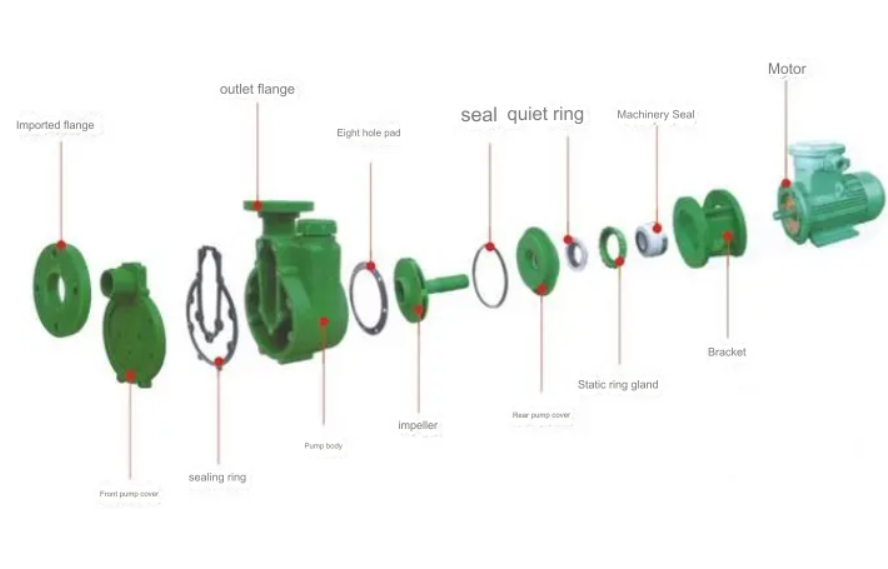

Assembly of self-priming sewage pump

The assembly of a self-priming sewage pump is a relatively complex but orderly process. The following are the assembly steps and precautions based on multiple sources:

1. Preparation before assembly

Check the parts: Make sure that all parts (such as pump body, motor, coupling, impeller, seal, etc.) are intact and meet the requirements of the product manual.

Prepare tools: Prepare the tools required for the assembly process, such as screwdrivers, wrenches, levels, measuring tools, etc.

2. Assembly steps

Install the base:

Place the base on the workbench to ensure that the base is stable and firmly fixed.

Install the motor:

Install the motor to the base to ensure that the connection between the motor and the base is tight and reliable.

For motors and pump bodies that require couplings to be connected, the coupling should be installed on the motor shaft first, and ensure that the coaxiality meets the requirements.

Install the pump body:

Install the pump body to the motor to ensure that the connection between the pump body and the motor is tight and reliable.

Be careful not to cut the O-ring rubber seal to ensure sealing performance.

Install the impeller:

Apply an appropriate amount of lubricating oil or stretching oil to the impeller keyway.

Install the impeller on the pump shaft, making sure that the impeller keyway is aligned with the pump shaft key.

Tighten the impeller nut and gasket using special tools (such as hook spanners and socket spanners).

Install seals:

Apply an appropriate amount of lubricating oil to the impeller side mechanical seal static ring, and wipe the mechanical seal sealing surface with a dust-free cloth.

Install the mechanical seal static ring pressure ring and pump cover, and fix the pump head and pump cover with bolts.

Install pipes:

Install the water inlet and outlet pipes as needed, and ensure that the pipes match the pump connection ports.

Use suitable sealing materials for connection, and ensure that the connection is tight and leak-free.

Filling lubricating oil:

Fill the pump body with an appropriate amount of lubricating oil or mechanical oil according to the requirements of the pump.

Install other accessories:

Install the valve plate and valve plate fixing bracket (if applicable).

Install accessories such as drain cover, water inlet and drain outlet plugs.

III. Debugging and inspection

Check the installation:

Check whether all parts are installed in place and whether the fastening bolts are tightened.

Check whether the pipe connection is well sealed and leak-free.

Debugging and running:

Turn on the power supply and conduct debugging and running.

Check the operation of the pump, such as whether the speed, flow rate, head, etc. meet the requirements.

Observe whether the pump body has abnormal noise or vibration. If there is any abnormality, stop the pump immediately for inspection.

Adjustment and optimization:

According to the debugging results, adjust and optimize the pump to ensure that the pump's operating performance reaches the best state.

IV. Precautions

Follow the instructions: During the assembly process, the operating steps and precautions in the product manual should be strictly followed.

Safety protection: Safety protection measures should be taken during the assembly process, such as wearing protective glasses and gloves.

Cleaning and inspection: Before assembly, the parts should be cleaned and inspected to ensure that there are no impurities and damage.

Level adjustment: During the installation process, a level should be used to adjust the horizontality and verticality of the pump to ensure that the pump can run smoothly.

Sealing inspection: When installing pipes and seals, special attention should be paid to the inspection of sealing performance to ensure that no leakage occurs.