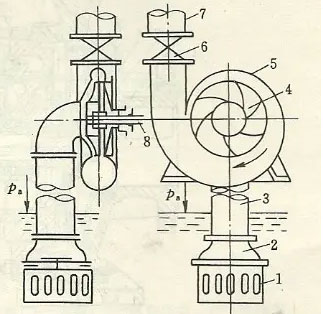

Assembly of single-stage single-suction centrifugal pum

The assembly of a single-stage single-suction centrifugal pump is a meticulous and important process, which directly affects the working performance and life of the pump. The following are the detailed steps and precautions for the assembly of a single-stage single-suction centrifugal pump:

1. Preparation before assembly

Read technical information: Carefully read the relevant technical information of the pump, such as the general drawing, parts drawing and instruction manual, etc., to understand the structure, performance parameters and assembly requirements of the pump.

Be familiar with the quality standards: Be familiar with the assembly quality standards of the pump to ensure that the technical requirements are met during the assembly process.

Check parts: Check whether the parts of the pump are complete and the quality is qualified, including key components such as the pump body, impeller, pump cover, shaft, bearing, etc.

Prepare tools: Prepare the tools and measuring tools required for the assembly process, such as wrenches, screwdrivers, vernier calipers, etc.

Prepare consumables: Prepare the consumables required for the pump, such as lubricating oil, sealant, asbestos packing, etc.

2. Assembly steps

Assemble the shaft group:

Assemble the bearing on the pump shaft, paying attention to the matching clearance and interference between the bearing and the shaft neck.

Use appropriate tools and methods (such as hand hammer, copper rod, sleeve or press, etc.) to install the bearing in place and ensure that the bearing fits tightly with the shaft neck.

Install the shaft assembly to the pump body:

Carefully install the assembled shaft assembly into the pump body, ensuring that the shaft and the bearing hole of the pump body fit correctly.

Adjust the height of the bearing gland and the torque of the tightening bolts to ensure the stability and sealing of the bearing.

Install the impeller:

Install the blades at the reserved tenon on the impeller hub and fix them with pins.

Install the impeller on the shaft and adjust its position to ensure that the gap between the impeller and the pump body meets the technical requirements.

Install the pump cover:

Drill holes in the center of the pump cover and weld them to install the inlet and outlet and bolt holes.

Install the pump cover on the pump body, seal it with bolts, and install the sealing gasket of the pump cover.

Install the mechanical seal:

Assemble the mechanical seal and fix its position with sealant.

Install the mechanical seal on the pump body together with the shaft, paying attention to the gap between the mechanical seal and the impeller.

Coupling alignment:

Install the coupling and adjust its position to ensure that the coaxiality deviation between the pump shaft and the motor shaft meets the technical requirements.

Use tools such as dial indicators to accurately measure and adjust to ensure the centering accuracy of the coupling.

Adding lubricating oil:

Add appropriate amount of lubricating oil or grease to the bearings and lubrication parts according to the requirements of the instruction manual.

Installation of the whole machine:

Install the assembled pump on the machine base, align and fix it.

Connect the pump's inlet and outlet pipes and accessories such as the motor to ensure a firm connection and reliable sealing.