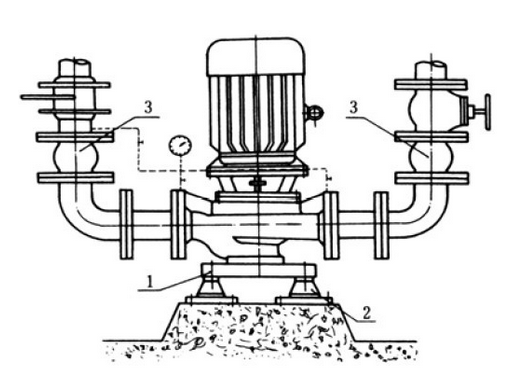

Calculation of installation height Hg of centrifugal pump

The calculation of the installation height Hg of a centrifugal pump is a process involving multiple factors, mainly including the allowable suction vacuum height Hs, the total resistance of the suction pipeline Hf0-1, the velocity V1 of the liquid at the pump inlet, etc. The following is a detailed calculation step and description:

I. Basic concepts

Allowable suction vacuum height Hs: refers to the maximum vacuum degree that can be achieved by the pressure p1 at the pump inlet. This value is experimentally determined by the pump manufacturer and attached to the pump sample for users to check. It should be noted that the Hs value given in the pump sample is usually measured under operating conditions of 20°C and a pressure of 1.013×10^5Pa with clean water as the working medium.

Installation height Hg: refers to the vertical height from the center of the centrifugal pump inlet to the liquid storage surface.

II. Calculation steps

Determine the correction value of the allowable suction vacuum height Hs

If clean water is transported, but the operating conditions are different from the experimental conditions (such as temperature, pressure, etc.), it needs to be corrected according to the formula. The correction formula is generally:

Hs1=Hs+(Ha−10.33)−(Hv−0.24)

Where Ha is the atmospheric pressure (unit converted to mH2O), and Hv is the saturated vapor pressure of liquid water (also converted to mH2O).

If other liquids are transported and the conditions are different from the experimental conditions, Hs must be corrected according to the above formula first, and then further converted according to the properties of the liquid.

Calculate the total resistance Hf0-1 of the suction line

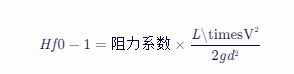

This step usually needs to be calculated based on factors such as the length, diameter, flow rate of the suction line, and the properties of the liquid. The specific formula may vary depending on the situation, but the general form is:

(阻力系数=resistance coefficient)Where L is the pipe length, V is the flow rate, d is the pipe diameter, and g is the acceleration of gravity.

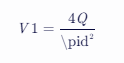

Calculate the velocity V1 of the liquid at the pump inlet

If V1 is not directly given in the question, it may be necessary to calculate based on the pump flow rate and pipe diameter. The formula is generally:

Where Q is the flow rate of the pump.

Calculate the installation height Hg

Finally, the installation height Hg can be calculated by the following formula:

Hg=Hs1-\frac{V1^2}{2g}-Hf0-1 \] Note that from a safety perspective, the actual installation height of the pump should be less than the calculated value. When the calculated Hg is a negative value, it means that the suction port of the pump should be below the liquid level of the storage tank.

3. Precautions

When calculating the installation height, ensure that all parameters are accurate and take into account various possible sources of error.

If conditions permit, it is best to conduct actual tests before installation to verify the accuracy of the calculation results.

Different calculation methods and formulas may be required for different types of pumps and different working conditions. Therefore, in specific applications, you should refer to relevant technical manuals or consult professionals.