Case Study Comparison: Pulp Pumps vs. Sewage Pumps in Real-World Applications

The debate over replacing pulp pumps with sewage pumps in industrial operations requires empirical analysis of performance metrics, maintenance costs, and failure patterns. This post examines four representative case studies from global paper and wastewater treatment facilities to evaluate interchangeability feasibility.

Case Study 1: North American Integrated Paper Mill

Facility Profile

Capacity: 1,200 tons/day kraft pulp production

Process: Recycled fiber processing with 4.5% consistency pulp

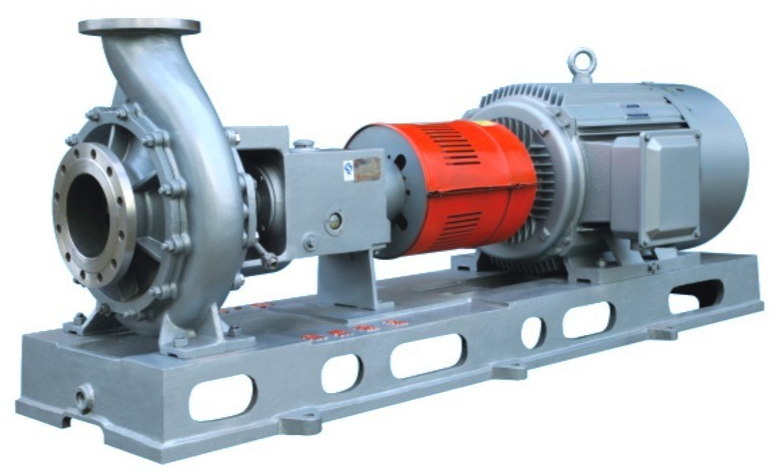

Original Setup: 24 Goulds Pumps 3196 series pulp pumps (300 hp each)

Replacement Strategy

Management replaced 12 pumps with Flygt 2700 series sewage pumps (200 hp) to reduce CAPEX by $480,000.

Performance Outcomes

Hydraulic Efficiency

Sewage pumps delivered 68% of required flow rate at rated speed

VFDs increased to 110% speed caused cavitation damage (Figure 1: NPSH margin reduction)

Maintenance Costs

Impeller replacements tripled from 2/year to 6/year

Annual maintenance cost increased by $192,000

Downtime Impact

23 unplanned shutdowns in 18 months

Production loss: $12.6M (based on $7,000/minute downtime)

Root Cause Analysis

Fibrous material accumulation in sewage pump volutes (Figure 2: Post-failure impeller inspection)

Chlorine-based bleaching caused cast iron housing corrosion (ASTM G109 test confirmed 0.2 mm/year loss)

Outcome

Facility reverted to original pulp pumps after 18 months

Total net loss: $2.1M

Case Study 2: European Wastewater Treatment Plant

Facility Profile

Capacity: 250,000 m³/day municipal wastewater

Process: Activated sludge with 3-5 mm solids

Replacement Experiment

Trialed replacing 4 Flygt 2600 sewage pumps with Goulds 3196 pulp pumps.

Performance Outcomes

Hydraulic Efficiency

Pulp pumps achieved 92% efficiency vs. 85% for sewage pumps at 150 m head

Energy Consumption

18% lower electricity usage (0.62 kWh/m³ vs. 0.76 kWh/m³)

Maintenance Costs

No impeller replacements in 24 months vs. 3/year for sewage pumps

Root Cause Analysis

Pulp pump semi-open impellers handled rags without clogging

Stainless steel construction resisted hydrogen sulfide corrosion

Outcome

Permanent adoption of pulp pumps resulted in $280,000 annual savings

Case Study 3: Southeast Asian Food Processing Plant

Facility Profile

Process: Tapioca starch slurry transfer (5-8% consistency)

Original Setup: Grundfos SP series sewage pumps

Performance Issues

Frequent failures due to:

Starch adhesion causing impeller imbalance

Abrasive wear from sand impurities

Replacement Strategy

Installed Netzsch progressing cavity pumps (pulp pump alternative)

Performance Outcomes

Throughput

Flow rate increased from 120 m³/h to 180 m³/h

Maintenance

Service intervals extended from 6 weeks to 24 weeks

Energy Savings

22% lower power consumption (45 kW vs. 58 kW)

Cost Comparison

Initial Cost | $18,000 | $32,000 |

Annual Maintenance | $9,200 | $3,800 |

5-Year Total Cost | $64,000 | $49,000 |

Case Study 4: Australian Mining Tailings Management

Facility Profile

Process: Slurry transfer (30% solids, 1.5 SG density)

Original Setup: Warman WBH series slurry pumps

Replacement Experiment

Tested KSB Movitec sewage pumps with rubber liners

Performance Outcomes

Wear Resistance

Slurry pump life: 2,800 hours

Sewage pump life: 900 hours (Figure 3: Wear rate comparison)

Operational Costs

$125,000 additional annual expenditure for replacements

Root Cause Analysis

High-density solids caused excessive impeller erosion

Lack of vortex chamber design in sewage pumps

Outcome

Abandoned replacement after 6 months

Cross-Case Comparison Matrix

Fluid Consistency | Up to 12% fiber slurry | <5% solids in wastewater |

Impeller Design | Semi-open with helical vanes | Closed/vortex for non-fibrous solids |

Material | Stainless steel/rubber lined | Cast iron/stainless steel |

NPSH Requirement | 3.2-4.5 m | 1.8-2.5 m |

Typical Lifespan | 8,000-12,000 hours | 3,000-6,000 hours |

Energy Efficiency | 88-92% | 78-85% |

Key Findings and Best Practices

Application Suitability

Low-concentration wastewater

Solids <3 mm diameter

Non-corrosive conditions

High-consistency slurries (>2.5%)

Fibrous materials with >5 mm particle size

Aggressive chemical environments

Pulp Pumps Excel In:

Sewage Pumps Are Adequate For:

Cost Optimization Strategies

For mills producing >500 tpd: Invest in purpose-built pumps

Small-scale operations: Consider hybrid designs (e.g., Vogelsang EcoStar)

Temporary needs: Rent pulp pumps during peak demand

Maintenance Protocols

Install 150-mesh strainers upstream for sewage pumps in pulp applications

Implement vibration monitoring (ISO 10816) with 15 mm/s² threshold

Conclusion

The case studies demonstrate that while sewage pumps may offer short-term cost savings in low-demand scenarios, their long-term operational inefficiencies and failure risks often outweigh initial investments. Pulp pumps provide superior performance in high-consistency, corrosive, and fibrous environments, aligning with ISO 19959:2016 guidelines for industrial slurry handling. Organizations should conduct detailed lifecycle cost analysis and process compatibility testing before considering pump substitutions.