Causes and solutions for gas blockage in sewage pump

The causes and solutions of sewage pump gas blockage are as follows:

1. Causes of sewage pump gas blockage

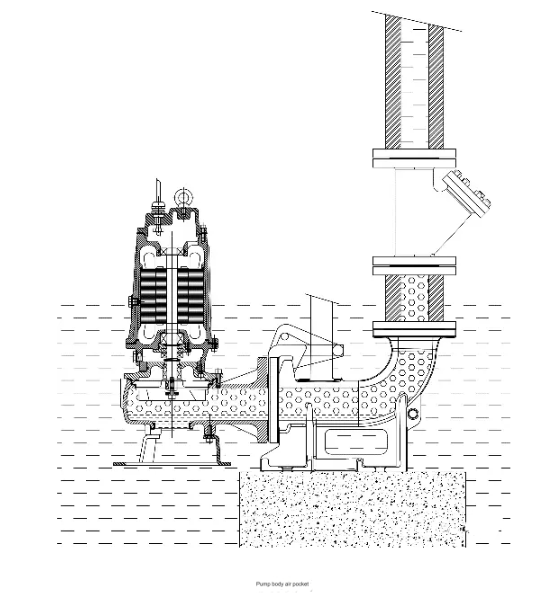

Gas accumulation after shutdown:

When the sewage pump is shut down, if the liquid level drops below the impeller, the pump and outlet pipeline may be blocked by gas when it is restarted. This is because the gas accumulates in the pipeline, causing the water level inside the pump body to be unable to rise to the height of the impeller, so that the impeller cannot contact the water and runs idle.

Improper pipeline design or maintenance:

Design defects such as pipe bends, sudden changes or no exhaust holes may cause gas accumulation in the pipeline, thereby affecting the normal operation of the sewage pump.

Improper operation:

Before starting the sewage pump, if the exhaust operation is not performed sufficiently or the exhaust operation is improper, it may also cause gas blockage.

2. Solutions to sewage pump gas blockage

Add a vent:

Open a vent on the pipe section from the pump outlet to the check valve to exhaust the gas accumulated inside the pump body. This is a direct and effective way to solve the problem of gas blockage.

Optimize pipeline design:

Check and optimize pipeline design, reduce bends and mutations in pipelines, and ensure that gas can be discharged smoothly. At the same time, add exhaust valves or exhaust holes at necessary locations to discharge accumulated gas in time during operation.

Strengthen exhaust operation:

Before starting the sewage pump, perform sufficient exhaust operation. You can open the exhaust valve or exhaust hole to let the gas discharge naturally. If there is a lot of gas accumulation, you can use manual exhaust tools to exhaust.

Adjust the installation angle:

When the water pump is in the pump body, you need to adjust the installation angle of the water pump so that it is installed correctly. This can reduce the accumulation of gas inside the pump body, thereby reducing the risk of gas blockage.

Regular maintenance and inspection:

Regularly maintain and inspect the sewage pump and pipeline system to ensure that each component is operating normally, and timely detect and deal with potential gas blockage problems. At the same time, replace worn parts according to usage to keep the equipment in good condition.

Use automatic exhaust device:

For some large or complex sewage pump systems, you can consider using an automatic exhaust device. This device can monitor the gas situation in the pipeline in real time and automatically perform exhaust operations when necessary, thereby greatly reducing the risk of gas blockage.