Chemical pump conveying medium type

Chemical pumps have a wide variety of conveying media types. According to the physical and chemical properties of the media, they can be divided into the following categories:

1. Liquid pumps

Liquid pumps are the most common type of chemical pumps and are mainly used to convey liquid media. It can be further subdivided into multiple types to meet different process requirements:

Clean water pumps: Suitable for conveying clean water or similar media that are non-corrosive and free of suspended solid particles. This type of pump is often used in cooling circulation, water supply and sewage treatment.

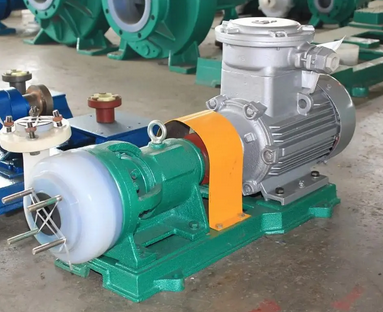

Corrosive liquid pumps: Made of corrosion-resistant materials, used to convey corrosive media such as acids, alkalis, and salt solutions. In ethylene production, this type of pump is used to convey corrosive media such as ethylene, butadiene, gasoline hydrogenation, polyethylene, and polypropylene.

High-temperature liquid pumps: Suitable for conveying high-temperature media such as hot oil, high-temperature solvents, etc. This type of pump is widely used in oil refining units and can handle liquid conveying under high temperature and high pressure environments.

2. Gas pumps

Gas pumps are mainly used to convey gaseous media. According to their specific functions, they can be divided into compressed gas pumps and vacuum pumps:

Compressed gas pumps: Used to convey compressed air, nitrogen, hydrogen and other gas media. This type of pump plays an important role in processes such as gas pressurization, gas transportation and gas circulation.

Vacuum pump: used to create and maintain a certain vacuum degree, commonly used in processes such as vacuum distillation, vacuum drying and vacuum extraction.

3. Mixed-phase pump

Mixed-phase pumps are used to transport mixed-phase media containing both solid particles and liquids or gases. This type of pump is suitable for conveying wastewater, ore slurry, petroleum slurry, etc. with suspended solid particles. According to the size and concentration of particles, mixed-phase pumps can be further subdivided into particle pumps, slurry pumps, etc.

Diversity in practical applications

In the petroleum industry, chemical pumps are particularly widely used. For example, centrifugal pumps in oil refining units are widely used in various units, such as atmospheric and vacuum distillation, catalytic cracking, coking, hydrogenation, etc. Hydrogenation feed pumps provide raw materials for various hydrogenation units, and their performance and materials must meet the requirements of high temperature, high pressure, corrosion resistance, etc. The oil slurry pump in the catalytic cracking unit needs to handle high-temperature oil slurry containing catalyst particles.

Summary:

The types of conveying media for chemical pumps include liquids, gases and mixed-phase media. Each type of pump has its specific application range and applicable conditions to meet the transportation needs of different chemical processes. When selecting a chemical pump, it is necessary to comprehensively consider factors such as the properties of the medium, process requirements, and environmental conditions.