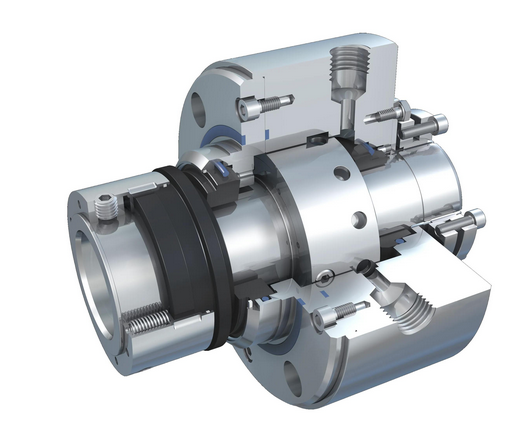

Chemical pump seal installation

The installation of chemical pump seals is an important step to ensure the sealing performance of the pump body, and the installation process needs to be meticulous and precise. The following is a detailed description of the installation of chemical pump seals:

1. Preparation

Tool preparation: Prepare the required disassembly and assembly tools, such as wrenches, screwdrivers, special disassembly tools, etc., and ensure that the tools are clean and intact.

Environmental preparation: Prepare a clean workbench or floor for the installation process to avoid the influence of debris and dust on the installation process.

Parts inspection: Confirm the cleanliness and integrity of seals, shafts, sealing chambers, glands and other parts. If there is damage or contamination, it should be handled in time.

2. Installation steps

Cleaning and lubrication:

Clean the shaft (or sleeve), sealing chamber, gland and other parts to ensure that there is no oil and impurities.

To reduce friction resistance, a thin layer of lubricating oil can be applied to the shaft (pay attention to the compatibility of rubber O-rings. If oil is not suitable, soapy water can be applied). The floating static ring is not suitable for anti-rotation pins, so it is not suitable to be oiled and should be installed dry into the gland.

Install the static ring:

Install the static ring and the gland on the shaft together, be careful not to touch the shaft, and ensure that the static ring is installed in the correct direction.

If there is an anti-rotation pin groove on the back of the static ring, the anti-rotation pin should be inserted into the corresponding hole of the sealing end cover first, and then the static ring should be installed so that the anti-rotation pin groove is aligned with the anti-rotation pin.

Inspection and adjustment:

Check the verticality of the sealing end face and the center line of the end cover and the flatness of the sealing end face to ensure that it meets the standard requirements.

Use tools such as optical flat crystals to check the flatness of the static ring end face. If there is any deformation, it should be ground.

Install the dynamic ring and spring assembly:

Put the two ends of the spring on the spring seat and the push ring respectively, and ensure that the spring is in close contact with the spring seat and the push ring.

Install the dynamic ring auxiliary seal ring into the dynamic ring and combine it with the push ring.

Gently install the assembled dynamic ring assembly on the pump shaft to ensure that the sealing surface of the dynamic ring and the static ring is in good contact.

Tightening and inspection:

Evenly tighten the gland bolts to make the gland fit tightly with the sealing chamber.

Check whether the seal has leakage, if any, it should be handled in time.

3. Precautions

Confirmation before installation: Confirm whether the installed seal is consistent with the required model, and carefully check the number of parts and installation position on the general assembly drawing.

Anti-rotation measures: For seals that need to be anti-rotated, ensure that the anti-rotation parts are installed in place to prevent the seals from rotating during operation.

Lubrication and sealing: During the installation process, attention should be paid to the treatment of lubrication and sealing to reduce friction resistance and prevent leakage.

Trial operation inspection: After the installation is completed, a trial operation inspection should be carried out to confirm that the pump unit is operating normally and the sealing performance is good.