Common faults and troubleshooting methods of submersible sewage pumps

This article mainly introduces the common faults and troubleshooting methods of submersible sewage pumps.

1. Insufficient flow or no water:

Possible reasons: motor reversal, flow channel blockage, excessive concentration of the pumped medium, too high lift of the device, severe wear of the impeller, too low liquid level causing the pump to inhale air, reverse installation of the check valve, etc.

Troubleshooting methods: Correct the motor direction, remove debris and set up a filter, flush the medium with water to reduce the concentration, try to reduce the lift of the device or use a pump with a higher lift, replace the impeller, adjust the position of the float switch, and correct the direction of the check valve.

2. Failure to start:

Possible reasons: phase loss, impeller stuck, winding joint or cable disconnection, stator winding burnout, control electrical failure, etc.

Troubleshooting methods: Check the circuit to eliminate the phase loss problem, remove debris, check with an ohmmeter and repair, repair and replace the winding or stator, check the control cabinet and repair or replace electrical parts.

3. Leakage:

Possible reasons: The mechanical seal surface of the submersible sewage pump used for a long time is severely worn, causing water to penetrate and immerse into the motor winding.

Troubleshooting: Place the submersible pump in a dry environment and replace the mechanical seal surface or "O" ring.

4. Low impeller speed:

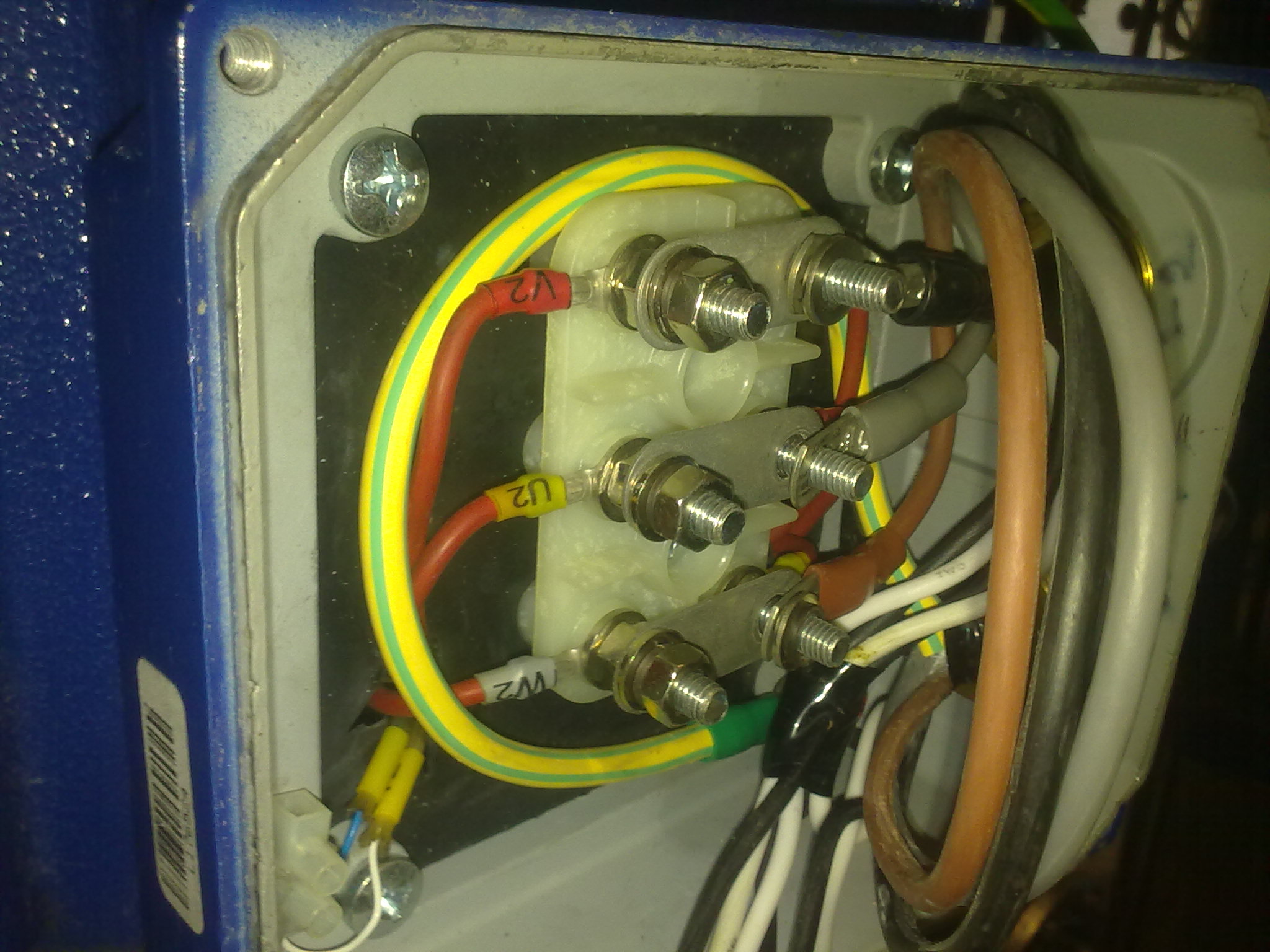

Possible cause: incorrect wiring.

Troubleshooting: Modify the wiring method, especially the connection of the fire line.

5. Power supply voltage problem:

Possible cause: The power supply voltage is too low, the cable is too thin and too long, resulting in excessive voltage drop.

Troubleshooting: Properly adjust the set current of the submersible sewage pump protection switch to ensure that the power supply voltage is within the appropriate range; for cable problems, appropriately thicken the cable segment or reduce the cable length.

6. Shutdown caused by the action of the thermal protector:

Possible cause: motor overload, impeller entangled by debris, bearing damage, etc.

Troubleshooting: Check and eliminate the cause of the overload, such as low power supply voltage, impeller stuck, etc., and automatically reset the thermal protection device after reducing the stator winding temperature.