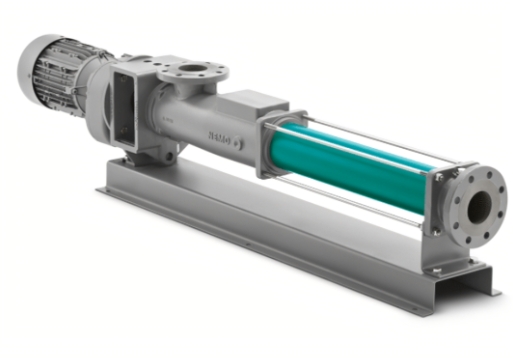

Common Faults in Screw Pumps and Their Causes

Introduction

Despite their reliability, screw pumps are not immune to faults. Identifying and addressing common faults is crucial for maintaining pump performance and preventing costly downtime. This post will explore the most common faults in screw pumps, their causes, and potential solutions, supported by real-world examples and data.

Common Faults and Causes

Cavitation: Cavitation occurs when the pump's suction pressure is too low, causing vapor bubbles to form and collapse, leading to damage. This is often caused by insufficient NPSH (Net Positive Suction Head) or clogged inlet filters.

Wear and Tear: The rotor and stator are subject to wear due to the abrasive nature of some fluids. Excessive wear can lead to reduced efficiency and eventual failure.

Overheating: Overheating can result from excessive friction, high fluid viscosity, or inadequate cooling. This can cause the stator to degrade and the pump to fail.

Leakage: Leakage can occur at the seals or between the rotor and stator, leading to reduced efficiency and potential contamination.

Real-World Example: Food Processing Industry

In a food processing plant, a screw pump used for transferring chocolate experienced frequent overheating. Analysis revealed that the high viscosity of the chocolate caused excessive friction, leading to overheating. The solution involved reducing the pump speed and installing a cooling system to maintain optimal operating temperatures.

Data Analysis

Cavitation: A pump operating at an NPSH of 2 meters experienced cavitation, reducing its efficiency by 15%. Increasing the NPSH to 4 meters eliminated cavitation and restored efficiency.

Wear and Tear: A pump handling abrasive slurry showed a 30% reduction in flow rate after 6 months of operation. Replacing the rotor and stator restored the pump's performance.

Overheating: A pump operating at 80°C experienced stator degradation within 3 months. Reducing the operating temperature to 60°C extended the stator's lifespan to 12 months.

Leakage: A pump with leaking seals lost 5% of its flow rate. Replacing the seals eliminated leakage and restored flow rate.

Conclusion

Identifying and addressing common faults in screw pumps is essential for maintaining their performance and reliability. By analyzing real-world examples and data, we can develop effective strategies for fault prevention and resolution.