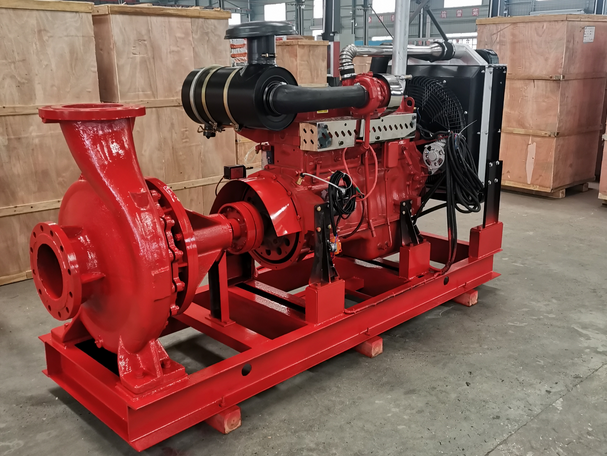

Composition and structure of diesel engine fire pump

The composition and structure of a diesel engine fire pump is relatively complex, but it can be summarized into the following core parts:

Diesel engine power part:

This is the power source of the entire system, usually composed of a diesel engine. The diesel engine generates power by burning diesel to drive the subsequent pump body to work. It includes a diesel tank, a fuel supply system (such as a fuel pump, a fuel injector, etc.), an ignition system (usually a compression ignition type, without a spark plug), a cooling system (such as a water tank, a radiator, a fan, etc.) and an exhaust system, etc.

Pump body part:

The pump body is the core component of a diesel engine fire pump, responsible for pressurizing and outputting the inhaled water. It usually consists of an impeller, a pump casing, a sealing device, etc. The impeller rotates under the drive of the diesel engine, throwing the inhaled water to the edge of the pump casing, thereby increasing the water pressure. The pump casing guides the water flow and fixes the impeller. The sealing device ensures that the pump body does not leak under high pressure.

Control system:

The control system is the brain of the diesel engine fire pump, responsible for monitoring and controlling the operating status of the entire system. It usually includes a programmable controller (PLC) or a microprocessor controller (MCU), sensors (such as pressure sensors, temperature sensors, etc.), actuators (such as solenoid valves, relays, etc.) and a human-machine interface (such as touch screens, indicator lights, buttons, etc.). The control system can monitor various system parameters in real time, such as the speed, temperature, pressure, etc. of the diesel engine, and automatically adjust the system's operating status, such as start, stop, speed regulation, etc., according to preset programs or external signals.

Accessories and auxiliary systems:

In addition to the above main parts, the diesel engine fire pump may also include some accessories and auxiliary systems, such as base, shock absorber, cooling fan, intake filter, exhaust muffler, battery, etc. These accessories and auxiliary systems can improve the performance and reliability of the diesel engine fire pump and ensure its stable operation in various complex environments.

Pipeline system:

The pipeline system includes suction pipes, outlet pipes, valves, etc., which are used to introduce fire water from the water source into the pump body and transport the pressurized water to where it is needed. The design of the pipeline system needs to consider factors such as water flow resistance and pressure loss to ensure smooth water flow and stable pressure.

The structure of a diesel engine fire pump is a highly integrated system. Each part cooperates and works together to ensure rapid response and stable water supply in fire emergencies.