Composition and structure of high viscosity asphalt cement pump

The composition and structure of high viscosity asphalt cement pumps (often referred to as asphalt pumps) may vary depending on their specific type and manufacturer, but in general, they mainly include the following key parts:

1. Pump body

Function: The pump body is the main part of the asphalt pump, which is used to accommodate and support other internal components and form a closed pump chamber in which the liquid can be compressed and transported.

Features: The pump body is usually made of corrosion-resistant and wear-resistant materials to cope with the special properties of media such as asphalt.

2. Impeller or rotor

Function: The impeller or rotor rotates in the pump body, and sucks and transports the medium such as asphalt to the outlet through the push of its blades.

Type: Depending on the type of pump, the shape and structure of the impeller or rotor will also vary. For example, in a centrifugal asphalt pump, the impeller usually has multiple backward curved blades; while in a volumetric asphalt pump (such as a screw pump, a gear pump), the liquid is transported by the relative movement of the rotor and the pump body.

3. Bearing

Function: The bearing is used to support and fix the rotating shaft of the impeller or rotor to ensure its stability and reliability during operation.

Features: Bearings usually have high load-bearing capacity and wear resistance to adapt to the long-term operation of asphalt pumps under harsh working conditions.

4. Sealing device

Function: The sealing device is used to prevent the liquid in the pump cavity from leaking into the external environment, and to prevent external impurities from entering the pump cavity.

Type: Common sealing forms include mechanical seals, packing seals, etc. These sealing devices need to be inspected and replaced regularly to ensure their sealing performance.

5. Driving device

Function: The driving device provides a power source for the asphalt pump so that it can work normally.

Composition: The driving device usually includes components such as motors and reducers. The motor transmits power to the impeller or rotor through the reducer, causing it to rotate and produce a pumping action.

6. Accessories and fittings

Including: inlet and outlet flanges, pressure gauge interfaces, safety valves, insulation jackets, etc.

Function: These accessories and fittings are used to connect pipelines, monitor pressure, ensure safety, and provide insulation, etc., to ensure that the asphalt pump can operate stably and efficiently.

In summary, the composition and structure of the high-viscosity asphalt cement pump is relatively complex, but the various parts work together to achieve stable delivery of high-viscosity asphalt and other media. In practical applications, it is necessary to select the appropriate asphalt pump type and specifications according to the specific working conditions and medium characteristics.

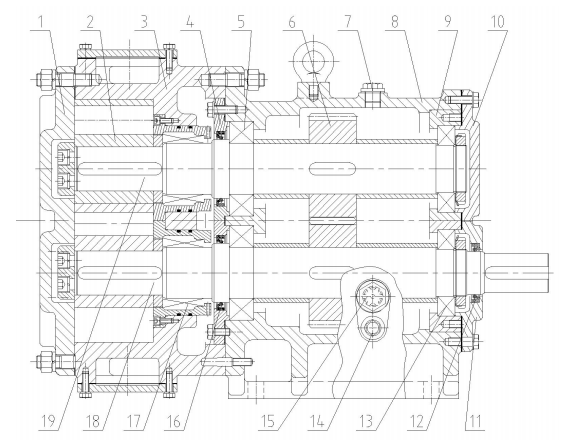

High viscosity asphalt cement pump profile

Front cover 2. Rotor 3. Pump body 4. Bearing cover 5. Bearing 6. Gear 7. Oil filling hole 8. Casing 9. Bearing sleeve 10. Bearing cover without hole 11. Bearing cover with hole 12. Skeleton oil seal 13. Bearing 14. Oil drain plug 15. Oil drain window 16. Skeleton oil seal 17. Mechanical seal 18. Driving shaft 19. Driven shaft

To learn more, please visit:

https://youtube.com/@gt-pump?si=gYw_o3qyY4rm5mCX