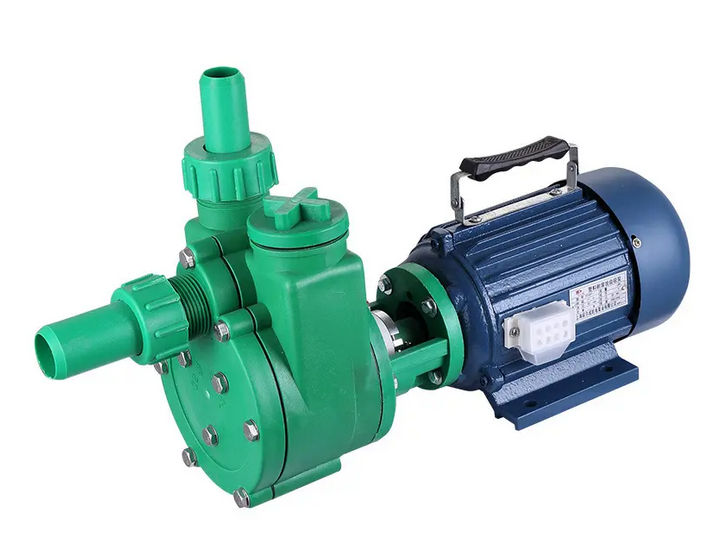

Composition of high temperature resistant strong acid centrifugal pump

High temperature strong acid centrifugal pump is a specially designed pump, mainly used to handle high temperature and strong acid liquid. Its composition mainly includes the following key parts:

1. Impeller

Function: The impeller is the core component of the centrifugal pump, responsible for transferring the rotational energy of the motor to the liquid, so that it obtains kinetic energy and pressure energy.

Features: The impeller is usually made of corrosion-resistant and high temperature resistant materials, such as stainless steel, special alloys or ceramics, etc., to adapt to strong acid and high temperature environments. The design of the impeller will also consider flow channel optimization to reduce energy loss and improve efficiency.

Type: According to specific needs, the impeller can be closed, semi-open or open, as well as backward curved blade type or twisted blade type, etc.

2. Pump body (pump casing)

Function: The pump body is the main part of the centrifugal pump, used to support and fix the impeller, and collect the liquid discharged from the impeller.

Features: The inner wall of the pump body is usually provided with a high temperature and corrosion resistant coating or lining, such as ceramics, Teflon, etc., to protect the pump body from high temperature and strong acid erosion. The design of the pump body also takes into account the flow characteristics of the fluid to ensure that the fluid can pass smoothly and reduce energy loss.

Structure: The interior of the pump body is usually designed in a volute shape to guide the fluid to gradually slow down and increase pressure.

3. Pump shaft

Function: The pump shaft is a component that connects the motor and the impeller, and is responsible for transmitting the motor's rotational motion to the impeller.

Features: The pump shaft is usually made of high-strength, corrosion-resistant materials such as stainless steel or alloy steel. The design of the pump shaft also takes into account balance and stability to ensure that the pump does not produce excessive vibration and noise when rotating at high speed.

4. Bearing

Function: The bearing is used to support the pump shaft and allow it to rotate smoothly.

Features: The bearing is usually made of high-temperature and corrosion-resistant materials, and is equipped with a lubrication system to reduce friction and wear.

5. Sealing device

Function: The sealing device is used to prevent the liquid in the pump from leaking out and air from entering the pump, ensuring the normal operation efficiency of the pump.

Type: Common sealing devices include mechanical seals, packing seals, etc. These sealing devices also need to have high-temperature and corrosion-resistant properties.

6. Other auxiliary components

Bottom valve: installed on the suction pipe to prevent liquid backflow when the pump is stopped.

Control valve: used to adjust the inlet and outlet flow of the pump.

Shield and bracket: provide additional safety protection and structural support.

The high temperature and strong acid resistant centrifugal pump components work together to ensure that the pump can operate stably and efficiently in high temperature and strong acid environments.