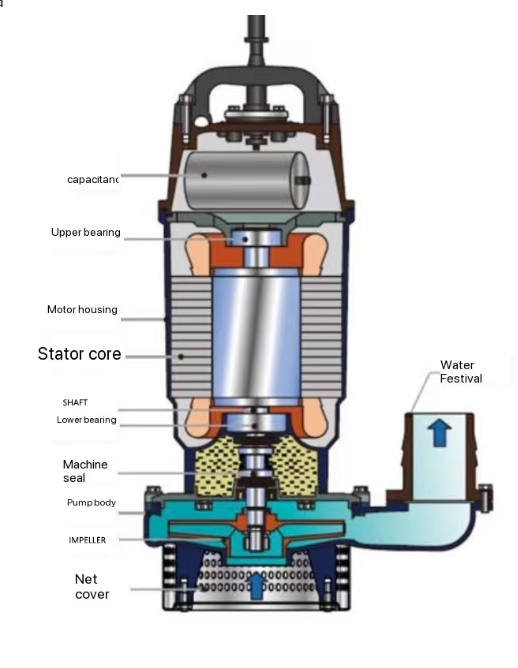

Composition of stainless steel submersible pump

Stainless steel submersible pumps are mainly composed of the following parts and key components:

I. Main parts

Water pump: responsible for pumping liquid from a low place to a high place or a designated location, and is the core component of a stainless steel submersible pump.

Submersible motor: provides power for the water pump so that it can work normally. Submersible motors are mostly closed water-filled wet, vertical three-phase asynchronous motors, which are waterproof and dustproof.

Water pipe: connects the water pump and the water outlet to transport the pumped liquid to the designated location. The water pipe is mostly made of steel pipes of different diameters and connected by flanges.

Control switch: used to control the start and stop of the submersible pump to ensure that the submersible pump can work normally when needed.

II. Key components

Stator: an important component for energy conversion of submersible pump motors, consisting of a housing, a stator core and a stator winding. The stator core is the magnetic conductor of the motor, and the stator winding receives electrical energy through cables and generates a rotating magnetic field.

Rotor: also a key component for energy conversion of submersible pump motors. The rotor interacts with the rotating magnetic field of the stator to generate electromagnetic torque and drive the motor to rotate. The rotor is composed of rotor core, balance washer, rotating shaft and other parts.

Bearing: The part that supports and fixes the rotor, usually a guide bearing is used, and the material is tin bronze or phenolic plastic. There are grooves on the inner surface of the bearing, and the water flow can take away the heat generated by the bearing.

Seals: There are two types of static seals and dynamic seals. Static seals are usually sealed with "O" type seals, while dynamic seals are sealed with integral seal discs, single-end mechanical seals, double-end mechanical seals, etc. The function of the seal is to prevent liquid leakage and ensure the normal operation of the submersible pump.

Wiring cavity and cable: used to connect the submersible pump to the external power supply. The cable and the motor winding lead are stably connected in the wiring cavity to ensure that the cable does not fall off during vibration, transportation and daily operation of the motor.

Impeller: The part that transfers the energy of the motor to the liquid. After the impeller rotates, the liquid is affected by the blades, and the pressure and speed increase. The impeller material varies according to the different occasions of use, such as cast iron, cast steel, stainless steel, etc.

Volute and guide vane: collectively referred to as the pressure chamber, the volute can collect the liquid flowing out of the impeller, reduce the liquid flow velocity, and increase the pressure energy. The guide vane plays the role of guiding the flow of liquid.

In addition, the stainless steel submersible pump may also include other auxiliary components, such as check valves, pressure regulating membranes, pressure regulating springs, packing seals, etc. These components work together to ensure the stable and efficient operation of the submersible pump.