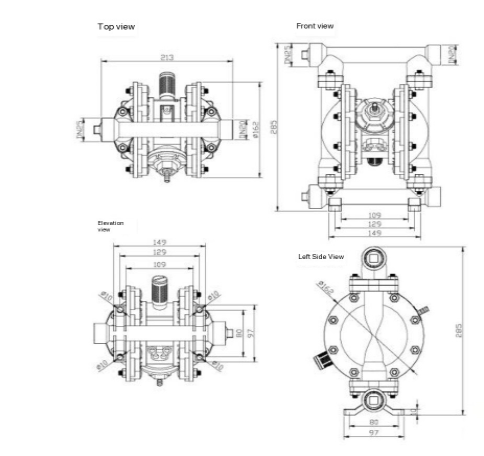

Cross-section structure of stainless steel diaphragm pump

Stainless Steel Diaphragm Pump Features

Easy to maintain and reduced internal volume to minimize waste and facilitate cleaning.

Stainless steel bolts resist corrosion and position accurately for easy reassembly. Precision matched components.

Wear-resistant end bearings ensure correct stem positioning and make replacement simple.

Protected discharge port

The discharge port adopts a common end to prevent vaporized liquid from corroding the air motor seal in the cavity. Downfeed function facilitates tank filling or unloading operations.

Rugged external structure

Corrosion-resistant structure prevents leakage and ensures clean replacement of liquids. Center components are aluminum with epoxy coating. Corrosion-resistant center components are 316 stainless steel.

Fluid compatibility

Available housing materials include aluminum, stainless steel, ductile iron, polypropylene, conductive polyoxymethylene or tetrafluoroethylene polymer. Reasonable seal design.

The diaphragm can be tightly locked to provide a reliable liquid seal.

Reliable heavy-duty diaphragm plate clamping device eliminates all leakage and displacement, avoiding downtime due to failure. The valve stem is designed to be durable.

300 series stainless steel stems offer longer service life and excellent corrosion resistance even in humid air.

Elastomeric material options

Various seat and ball options ensure fluid compatibility and reliable sealing, resulting in longer service life and better suction height.

Stainless steel diaphragm pump profile: