Design features and performance evaluation of gear pumps

As a common liquid conveying equipment, the design features and performance evaluation of gear pumps are mainly reflected in the following aspects:

Design Features

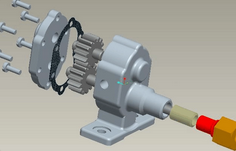

Compact structure: The design of gear pumps is known for its compact structure, and the pump body is usually made of strong and durable cast iron or cast steel. The pump is equipped with two intermeshing gears that rotate to transport fluid. This structure makes the gear pump very convenient to install and use in a limited space.

Smooth operation: The gear pump exhibits high efficiency and energy saving characteristics during operation. Its unique structural design makes the fluid flow more smoothly in the pump and reduces energy loss. At the same time, the optimized design of rotating parts makes the pump run more smoothly and reduces vibration and noise.

Wide range of applications: Gear pumps are suitable for transporting fluids of various viscosities, including low viscosity, high viscosity and fluids containing particles. This wide applicability makes gear pumps widely used in many fields such as petroleum, chemical industry, food and pharmaceuticals.

Simple maintenance: The gear pump has a relatively simple structure, fewer parts, and is easy to disassemble and assemble. This design not only facilitates repair and maintenance, but also effectively extends the service life of the equipment.

Performance evaluation

Efficient and stable: The gear pump achieves efficient liquid transportation through the rotation of gears. Its design provides stable flow and pressure to ensure continuous delivery of liquid.

Flow and pressure: The flow and pressure performance of a gear pump are important indicators for its performance evaluation. Through professional testing equipment, parameters such as the maximum flow rate and maximum discharge pressure of the gear pump can be measured to evaluate whether its performance meets the usage requirements.

Noise and vibration: The noise and vibration generated by the gear pump during operation are also important indicators for evaluating its performance. Through on-site testing, it is possible to evaluate whether the gear pump's noise and vibration levels comply with environmental standards and usage requirements.