Comparative Analysis: Diesel Engine Fire Pump vs Electric Pump: Pros and Cons

Diesel engine fire pumps and electric pumps each have their own merits and drawbacks when it comes to firefighting applications. Understanding these differences is crucial for effective emergency response.

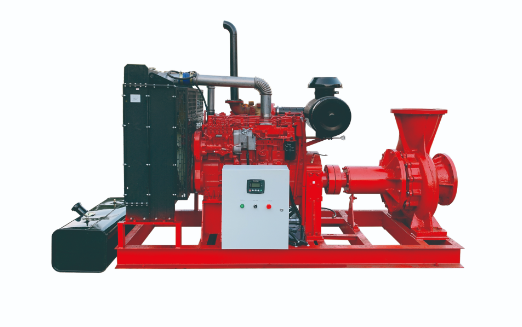

Advantages of Diesel Engine Fire Pumps:

Uninterrupted Operation: Diesel engines can run for extended periods without an external power source, making them ideal for remote or emergency situations where electricity may not be available.

High Power Output: With high torque capabilities, diesel pumps can deliver substantial flow rates even under heavy loads, crucial for combating large-scale fires.

Reliability: Diesel engines are known for their durability, and they are less prone to failure during intense firefighting operations.

Disadvantages of Diesel Engine Fire Pumps:

Noise & Emissions: Diesel engines produce noise and exhaust fumes, which may be undesirable in residential areas or environmentally sensitive zones.

Maintenance: They require regular maintenance and fuel, adding complexity to logistics and increasing operational costs.

Electric Fire Pumps:

Ease of Use: Electric pumps are easy to operate, requiring minimal training and minimal start-up time.

Environmental Friendliness: They produce no emissions, making them a cleaner choice in urban environments.

Regulatory Compliance: Many areas prefer electric-powered equipment due to emission regulations.

Drawbacks of Electric Fire Pumps:

Dependence on Grid: Electricity supply is critical, and power outages can disable pumps, compromising response times.

Energy Consumption: Electric pumps can be energy-intensive and may struggle during prolonged high-demand situations.

In conclusion, both diesel and electric fire pumps have their strengths and weaknesses. The choice depends on the specific needs, location, and emergency preparedness of the firefighting system. Understanding these trade-offs helps decision-makers select the most suitable option for their context.