Electrical system maintenance for sewage pumps

The electrical system maintenance of the sewage pump is an important part to ensure its normal operation and extend its service life. The following is a detailed description of the electrical system maintenance of the sewage pump:

1. Cable line and motor inspection

Cable line inspection:

Regularly check whether the cable line is damaged, aged or in poor contact.

Find problems and repair them in time to avoid electrical faults such as short circuit and open circuit.

Motor inspection:

Check the operating status of the motor, including whether the current, voltage and other parameters are normal.

Pay attention to the temperature rise of the motor to ensure that the motor runs under rated load to avoid overheating damage.

2. Protection device inspection

Install protection devices:

Install leakage protectors, air switches, fuses and other protection devices on the electrical system to ensure that the power supply can be cut off in time when an electrical fault occurs.

Regular inspection:

Regularly inspect and test the protection device to ensure that it is in normal working condition.

Once the protection device is found to be faulty or ineffective, it should be stopped immediately for replacement or repair.

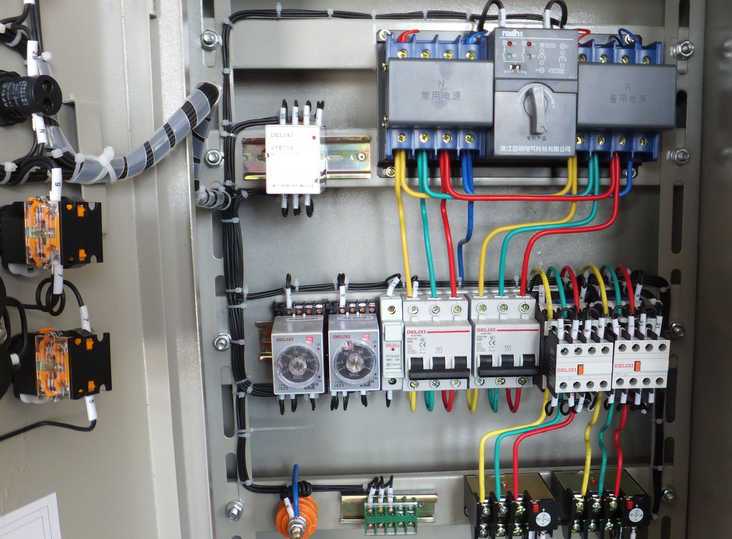

3. Maintenance of electrical control box and distribution box

Anti-corrosion treatment:

Regularly perform anti-corrosion treatment on the electrical control box and distribution box, remove the failed paint and rusty surface, and apply new paint.

Insulation inspection:

Check whether the insulation of electrical equipment is damaged and whether the insulation resistance is qualified.

Ensure that the electrical connection parts are firm and intact to avoid electrical faults such as leakage or short circuit.

4. Safe use of electricity and operating specifications

Safe voltage:

Electrical equipment such as portable running lights used in humid environments must use a safe voltage below 36V, especially less than 12V in humid environments.

Standard operation:

Non-electrical technicians are not allowed to operate and disassemble electrical equipment.

Damaged electrical equipment must be repaired by electrical technicians.

The metal casing of electrical equipment must have a qualified grounding wire to ensure safe use of electricity.

Safety education and activities:

Regularly conduct safety education activities for operators to learn about safe use of electricity.

Improve the safety awareness of operators and reduce the occurrence of electrical accidents.

5. Other precautions

Waterproof and moisture-proof:

Electrical equipment should be well protected from rain and water, and accumulated water should be removed in time to prevent the equipment from getting damp.

Regular maintenance:

Develop a regular maintenance plan for electrical equipment and implement it as planned.

Maintenance includes cleaning equipment, tightening screws, replacing damaged parts, etc.

Records and files:

Establish maintenance files for electrical equipment, record the time, content, problems found and solutions for each maintenance, etc.

Provide reference for subsequent equipment management and maintenance.