Energy-saving transformation plan for industrial pumps

The energy-saving transformation plan of industrial pumps is a key measure to improve production efficiency and reduce energy consumption. Here is a concise yet comprehensive overview of the renovation plan:

Industrial pump energy-saving renovation plan

1. Assessment and Diagnosis

First, conduct a comprehensive energy consumption assessment and diagnosis of the existing industrial pump system to identify links and causes of high energy consumption. By measuring operating power, accumulated power and operating time in real time, energy consumption data can be accurately grasped to provide scientific basis for subsequent transformation.

2. Application of variable frequency speed regulation technology

Introduce variable frequency speed regulation technology to adjust the operating frequency and speed of the water pump according to actual needs, so that the water pump output matches the actual load. This not only effectively avoids the waste of regular fixed-speed operation, but also significantly reduces energy consumption when flow demand decreases. For example, when the flow demand is reduced by half, only 12.5% of the rated power is theoretically required, and the energy saving effect is significant.

3. Optimize system design and layout

Properly plan the layout of water pumps and pipeline connections to reduce pipeline resistance and losses and avoid excessively long and thin pipeline designs. Optimize the structure and design of the pump body, such as improving the design of impellers, casings and other components, reducing fluid resistance and improving pump efficiency. At the same time, more advanced materials and manufacturing processes are used to reduce pump friction and energy loss.

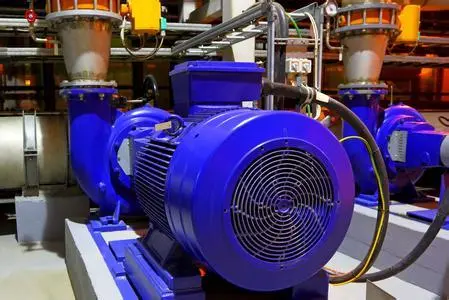

4. Choose energy-saving water pumps and efficient motors

Replacing pumps and motors with high-efficiency and energy-saving features can significantly reduce energy consumption. These new types of equipment have more advantages in design, manufacturing, control, etc., and can significantly improve energy utilization and operating efficiency.

5. Regular maintenance and monitoring

Establish a regular maintenance and monitoring mechanism to regularly check the seals, bearings, lubricating oil and other components of the water pump to keep the equipment in good condition. Monitor the working status of the inverter, system operating parameters, current and voltage in real time to ensure the safe operation of the system, detect and deal with potential problems in a timely manner, and avoid unnecessary increases in energy consumption.

6. Implement parallel and series control strategies

For systems that require multiple water pumps to work together, parallel and series control strategies are used to reasonably arrange the operating status of the water pumps according to actual needs to avoid unnecessary energy consumption.