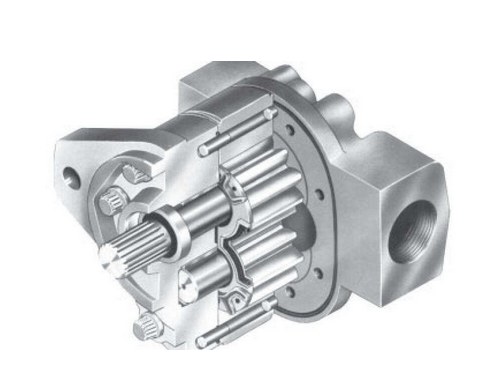

Features of precision gear pumps

The characteristics of precision gear pumps are mainly reflected in the following aspects:

1. High precision and stability

Precise flow: Precision gear pumps use precise gear design and manufacturing technology to ensure high precision and stability of flow, and are suitable for application scenarios that require precise flow control. The metering accuracy can be as high as ±1%, and even in some cases it can reach 0.3% metering accuracy.

Stable pressure: Through improved gear parameter design and optimized melt flow channel design, precision gear pumps can output more stable pressure and adapt to precision extrusion conditions.

2. High efficiency and durability

Efficient transmission: Precision gear pumps have high efficiency in transmitting fluids, which can reduce energy consumption and improve production efficiency.

Long-term stable operation: The use of high-quality materials and manufacturing processes ensures the long-term stable operation and long service life of precision gear pumps, reducing maintenance costs.

Wear-resistant materials: The pump head material is available in a variety of options, such as high-temperature tool steel, chromium-nickel alloy steel, stainless steel, Hastelloy, titanium alloy, etc., suitable for metering, transportation, sampling, etc. of various acids, alkalis, solvents and chemical additives.

3. Diversity and flexibility

Multiple sealing methods: Precision gear pumps have multiple sealing methods, good sealing performance, and can adapt to the needs of different media and working conditions.

Multiple drive methods: Optional drive methods, such as IEC standard motors, ATEX explosion-proof motors, brushless DC motors, servo motors, etc., provide more choices and flexibility.

Multiple installation methods: Precision gear pumps have multiple installation methods to meet the personalized needs of users.

4. Adaptability and extensiveness

Wide range of adaptability: Precision gear pumps can be used for high pressure difference, high system pressure and a wide range of medium viscosity, including various solvents, strong acids and alkalis, and higher viscosity media.

Wide application field: Precision gear pumps play an important role in industrial production and are widely used in various occasions that require precise flow control and stable pressure output, such as chemical, pharmaceutical, food, hot melt adhesive and other fields.

In summary, precision gear pumps have important application value in industrial production with their high precision, high efficiency, durability, diversity and flexibility, and wide adaptability.