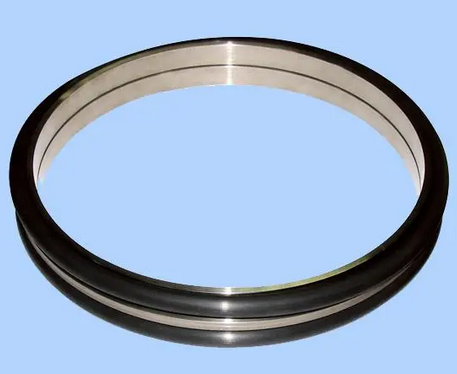

Floating ring seal for water pump

The floating ring seal of the water pump is an important shaft end seal form. It is mainly used to reduce the axial leakage of the fluid in the pump and prevent external impurities from entering the pump. The following is a detailed analysis of the floating ring seal of the water pump.

I. Sealing principle

The floating ring seal is a non-contact dynamic seal that relies on the extremely small gap between the floating metal ring and the shaft or housing to limit fluid leakage. The floating ring can float freely in the housing, so when the shaft rotates at high speed and vibrates, the impact on the seal is small, and the friction and wear are also small. The floating ring seal is to achieve radial sealing by maintaining close contact between the sealing end faces of the floating ring and the support ring under the action of liquid pressure and spring force; at the same time, the small gap formed by the inner circular surface of the floating ring and the outer surface of the shaft sleeve throttles the liquid to achieve axial sealing.

II. Structural composition

The floating ring seal is mainly composed of several single ring sleeves arranged in sequence on the shaft. Each single ring is composed of a floating ring, a support ring and three springs. The sealing end faces of the floating ring and the support ring maintain close contact under the action of liquid pressure and spring force to form a sealing surface. At the same time, a small gap is maintained between the inner circle surface of the floating ring and the outer surface of the sleeve, and axial sealing is achieved through throttling.

3. Features

High-speed sealing: The floating ring seal is a high-speed seal suitable for high-speed water pumps.

Non-contact sealing: Since the floating ring can float freely in the housing, there is no direct contact with the shaft or housing, which reduces friction and wear.

Good sealing effect: Through the closely contacted sealing end face and the tiny throttling gap, the floating ring seal can effectively prevent fluid leakage.

Strong adaptability: The floating ring seal has a certain adaptability to the vibration and eccentricity of the shaft, and can maintain the sealing performance to a certain extent.

4. Application occasions

Floating ring seals are widely used in various water pumps that require high-speed and high-efficiency sealing, especially in the chemical, petroleum, electric power and other industries, where high sealing performance is required.

5. Maintenance and care

In order to maintain the good performance of the floating ring seal, regular maintenance and care are required. Specific measures include:

Regularly check whether the sealing end faces of the floating ring and the support ring are worn or damaged, and replace them in time if necessary.

Check whether the gap between the floating ring and the sleeve is appropriate. Too large or too small will affect the sealing effect.

Keep the sealing cavity clean and lubricated to prevent impurities and dirt from entering and affecting the sealing performance.

Pay attention to the operating status of the water pump. If there is abnormal vibration or noise, check and deal with it in time.