Fluid Dynamics Analysis and Optimal Design of Pumps

The fluid dynamics analysis and optimization design of the pump is a comprehensive process involving multiple technologies and methods. The fluid dynamics analysis and optimization design of the pump is a key process to improve the performance, efficiency and reliability of the pump. The following is a clear summary of this:

1. Fluid dynamics analysis

Parameter calculation and analysis:

Involving key parameters such as flow, head, pressure and flow rate. Through real-time monitoring and analysis of these parameters, we can have a deep understanding of the working status and efficiency of the pump.

For example, the flow rate represents the volume of fluid delivered by the pump per unit time (unit: liters/second or cubic meters/hour), and the head reflects the height to which the fluid is pressurized (unit: meter).

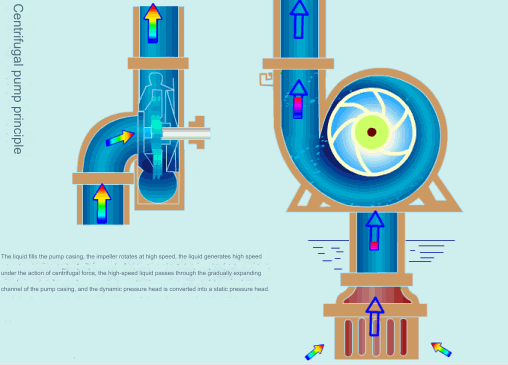

Fluid mechanics characteristics simulation:

Use computer-aided design software to simulate and simulate the fluid movement in the pump to reveal the fluid dynamics characteristics.

Through simulation, we can find out the flow law, pressure distribution and energy conversion efficiency of the fluid in the pump.

Qualitative and quantitative analysis:

Qualitative analysis is based on the principles of mechanics and energy conservation, such as the principle of momentum and the principle of energy conservation, to theoretically explore the working process of the pump.

Quantitative analysis uses numerical calculations and computer simulations to accurately solve the performance parameters of the pump, such as efficiency and power.

2. Optimization design

Structural improvement:

For the problems found in the fluid dynamics analysis, the key components of the pump, such as the impeller and seal, are structurally optimized.

For example, the impeller design is improved to reduce energy loss and friction resistance and improve the conversion efficiency of the pump.

Parameter adjustment:

According to different working conditions, the working parameters of the pump, such as speed, flow rate and pressure, are adjusted.

By optimizing the working parameters, the pump can maintain high performance under different working conditions.

Pipeline layout optimization:

Optimize the pipeline layout and pipeline material selection to reduce pressure loss and flow resistance.

This helps to improve the delivery efficiency and stability of the pump and reduce operating costs.