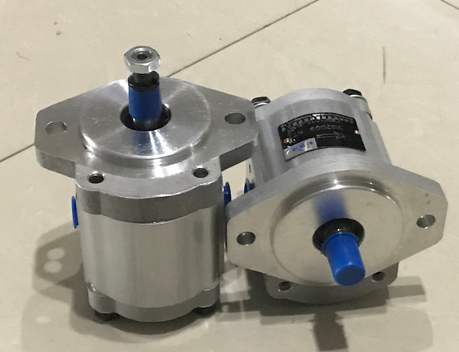

Gear pump gear type

There are many types of gears in gear pumps. According to different classification standards, they can be divided into the following categories:

1. Classification by gear meshing form

External meshing gear: It consists of two external gears, one of which is the driving wheel and the other is the driven wheel. The two gears have the same number of teeth, and the tooth shape is mostly straight teeth. The gears are tightly engaged to form a sealed cavity. During the rotation of the gears, the volume of the sealed cavity changes continuously, thereby realizing the suction and discharge of the liquid. The external gear pump has the advantages of simple structure, small size, and low noise, and is suitable for low pressure and low flow occasions.

Internal meshing gear: It consists of an internal gear and an external gear. The tooth shape of the internal gear is straight teeth, and the tooth shape of the external gear is arc teeth. During the rotation of the internal gear, the liquid is sucked into the tooth groove of the gear and then pushed to the outlet of the tooth groove for discharge. The internal gear pump has the advantages of large delivery volume, high pressure, and long service life, but the structure is more complicated and the manufacturing cost is also higher. It is suitable for high pressure and high flow occasions.

2. Classification by tooth curve

Involute tooth form: The tooth shape of the gear is involute, which enables the gear to smoothly transmit torque during meshing and reduce vibration and noise. Gear pumps with involute teeth are widely used in hydraulic systems.

Cycloid type: The tooth shape of the gear is cycloid, which has higher transmission efficiency and better sealing performance. Cycloid gear pumps have unique advantages in some special occasions.

3. Classification by tooth surface form

Spur gear: The tooth surface is straight line, with simple structure and convenient processing, but the impact and vibration are large during meshing.

Helical gear: The tooth surface is oblique, which can reduce the impact and vibration during meshing and improve the stability and service life of the gear pump.

Herringbone gear: The tooth surface is herringbone, composed of two helical gears, with better meshing performance and higher transmission efficiency.

Gear with circular arc tooth surface: The tooth surface is circular arc, which can provide better sealing performance and higher pressure bearing capacity.

4. Special types

Double arc gear: A special type of gear, consisting of two meshing gears, one of which has an arc tooth shape and the other has a double arc tooth shape. Double arc gear pumps have the advantages of large delivery volume, high pressure, and low noise, but their gears are difficult to manufacture and the cost is also high.

When choosing a gear pump, you need to choose the appropriate gear type according to the specific use requirements and working environment.