General installation method of stainless steel multi-layer centrifugal pump

Stainless steel multistage centrifugal pump is a commonly used industrial fluid conveying equipment. Correct installation is essential for the normal operation of the pump. The following is the general installation method of stainless steel multistage centrifugal pump:

1. Determine the installation location: First, you need to determine the installation location of the stainless steel multistage centrifugal pump. The installation location is required to be flat, stable, and convenient for maintenance and repair.

2. Install the foundation: At the determined installation location, the foundation needs to be installed to ensure that the foundation is flat and firm to reduce the vibration and noise of the pump during operation.

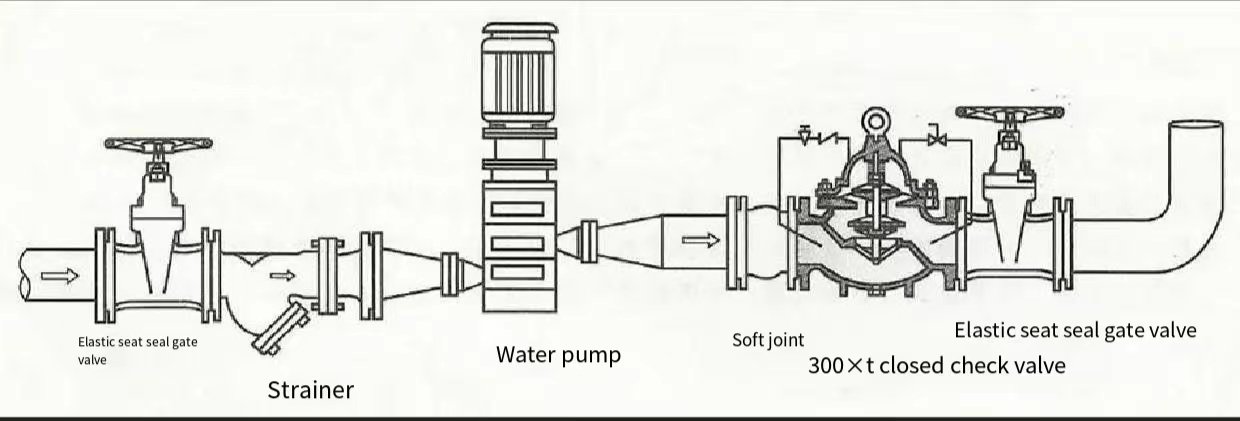

3. Install the inlet and outlet pipelines: According to the process requirements and on-site layout, correctly connect the inlet and outlet pipelines, and ensure the sealing performance and firm connection of the pipeline to avoid leakage.

4. Install the bracket: According to the size and weight of the stainless steel multistage centrifugal pump, install the bracket to ensure that the support of the pump is firm and stable.

5. Install the motor: According to the working requirements of the pump, correctly install the motor, connect the connecting parts of the motor and the pump, and ensure that the connection between the motor and the pump is firm.

6. Adjust the position of the pump: According to the actual situation, adjust the position of the stainless steel multistage centrifugal pump to ensure that the connecting axis of the pump and the motor is parallel, and the inlet and outlet of the pump are aligned with the pipeline.

7. Grounding and wiring: Ground and wire the installed stainless steel multistage centrifugal pump to ensure that the circuit is safe and reliable.

8. Inspection and trial run: After the installation is completed, conduct a comprehensive inspection of the pump to ensure that all components are firmly connected and not loose. Then conduct a trial run to check the operating status and working performance of the pump to ensure the normal operation of the pump.