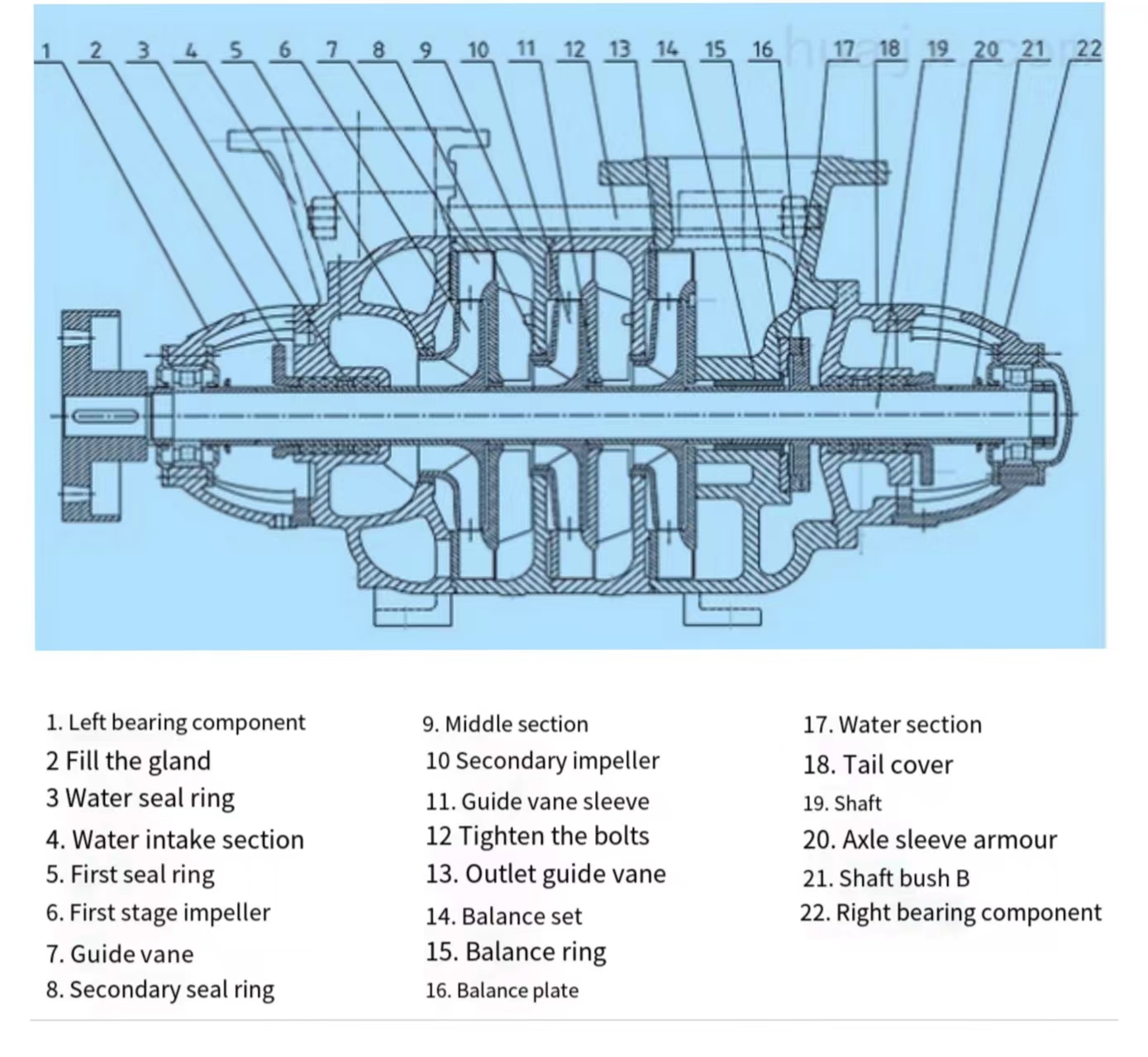

General structure of stainless steel multistage centrifugal pump

The structure of the stainless steel multistage centrifugal pump can be clearly divided into several main parts to ensure its efficient and stable operation. The following is a detailed explanation of its structure:

Stator part:

The stator part is mainly composed of the suction section, the middle section, the discharge section and the guide vane, etc. These parts are tightly clamped together by tightening bolts to form a complete studio. For D-type pumps, it is usually designed to suck horizontally and discharge vertically upward, which is suitable for various drainage and water supply occasions.

The guide vane plays a key role in the stator part. It guides the fluid from the first-stage impeller to the next-stage impeller to ensure a smooth transition of the fluid.

Rotor part:

The rotor part includes key components such as shaft, impeller, balance disc and sleeve. The shaft is the core of the rotor, which supports all rotating parts and is connected to the prime mover through an elastic coupling.

The impeller is one of the most important parts in a centrifugal pump. It is responsible for converting mechanical energy into kinetic energy and static pressure energy of the fluid. The impeller is usually made of stainless steel with high hardness and wear resistance.

The balance disc is used to balance the axial force of the rotor to ensure the stable operation of the pump.

Bearing part:

The bearing part is mainly composed of bearing body, bearing and bearing cover, etc., which is used to support the rotation of the rotor. The bearing is usually lubricated with grease or thin oil to ensure its good operating condition.

Shaft seal part:

The shaft seal is a key sealing device in stainless steel multistage centrifugal pumps, which is used to prevent fluid leakage in the pump. The shaft seal usually adopts soft packing seal or mechanical seal, which is selected according to user needs and specific working conditions of the pump.Other parts:

In addition to the above main parts, stainless steel multistage centrifugal pumps also include other auxiliary components, such as couplings, bases, inlet and outlet flanges, etc., which together ensure the stable operation and installation convenience of the pump.