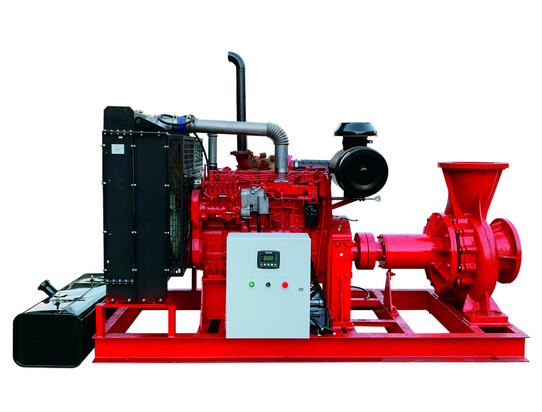

High-efficiency and energy-saving diesel engine fire pump technology

High-efficiency and energy-saving diesel engine fire pump technology is an important development direction in the current fire equipment field. The following is a detailed analysis of the characteristics, advantages and application areas of this technology:

1. Technical characteristics

High efficiency:

The diesel engine generator set has a strong power output and can continuously provide a high-flow, high-pressure water source for a period of time to meet the needs of the fire protection system.

The CFD (computational fluid dynamics) technology is used to optimize the flow channel design of the pump to ensure that the pump has an efficient hydraulic shape line and improve the efficiency of the pump.

Energy-saving design:

As a power source, the diesel engine has a high energy density and relatively high fuel efficiency, which can reduce energy consumption while ensuring power output.

By optimizing the matching of the engine and the pump, energy loss is reduced and overall energy efficiency is improved.

High degree of automation:

Modern diesel engine fire pumps are usually equipped with automatic control systems, which can automatically start or stop according to actual needs to ensure rapid response and effective operation in the event of a fire.

It has functions such as automatic start, automatic alarm, automatic charging, automatic preheating, and generally has automatic, manual and fault self-checking functions to monitor the working conditions throughout the process.

Easy installation and maintenance:

The vertical pipeline structure allows the pump inlet and outlet to be installed at any position and direction of the pipeline like a valve, which is extremely convenient for installation and maintenance.

The modular design makes component replacement and maintenance faster.

Smooth operation, safe and reliable:

The motor and pump are directly connected, which simplifies the intermediate transmission structure and enhances the smoothness of operation.

The diesel engine fire pump unit has a large overall crankshaft, high rigidity, high strength, and high torque transmission efficiency, which makes the unit run smoothly, safely and reliably.

Strong durability:

The mechanical seal position of the shaft is inlaid with a stainless steel sleeve to avoid rust, increase the life of the shaft, and reduce the cost of operation and maintenance.

The high-quality materials and advanced processes are used to ensure that the equipment can still operate stably for a long time in harsh environments.

2. Advantages

Strong adaptability: Diesel engine fire pumps can work in harsh environments, including extreme temperatures, humidity and pollution conditions. In addition, its flexible design makes it suitable for firefighting tasks of different sizes and types.

High economy: Although the cost of diesel may fluctuate, the overall energy conversion efficiency of the diesel engine is high, which can reduce operating costs in long-term use.

Low noise: High-quality diesel fire pumps have done a lot of optimization work in noise reduction, so that the noise index reaches the national standard for superior products.

3. Application areas

Industrial parks, chemical plants: Due to the presence of many flammable materials, diesel fire pumps are an important part of safety protection, providing a fast and effective water source for fire protection facilities.

Large construction sites: Temporary fire protection facilities are usually required to prevent fire accidents. Diesel fire pumps can provide water sources for the project site to ensure safety during the construction process.

Agricultural irrigation: Diesel fire pumps are not only used for fire fighting but also for agricultural irrigation. They can efficiently transport water to the fields, improve irrigation efficiency and water utilization.

Areas with insufficient or unstable power supply: The use of diesel fire pumps in these areas can be unaffected by factors such as insufficient or fluctuating power supply, ensuring the normal operation of the equipment.