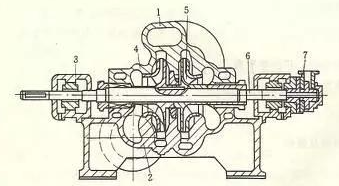

Horizontally split multistage centrifugal pump structure

The figure below shows the structure of a horizontally split multistage centrifugal pump. This pump uses a volute-shaped pump body, and each impeller has a corresponding volute chamber on the periphery, which is equivalent to installing several single-stage volute pumps on the same shaft to work in series, so it is also called a volute multistage pump.

(1 pump cup, 2 pump body, 3 bearing body; 4 shaft sleeve; 5 impeller; 6 pump shaft; 7 shaft head oil pump)

Because the pump body is horizontally split, the suction port and the discharge port are directly cast on the pump body, which is very convenient for maintenance. Just remove the pump cover to expose the entire rotor. When repairing the rotor, the entire rotor needs to be lifted out without disassembling the connecting pipeline.

The impellers of this pump are usually arranged in an even number of symmetric arrangements, and most of the axial forces are balanced, so there is no need to install an axial balancing device.

The flow range of the horizontally split multistage pump is 450~1500m/h, and the maximum head can reach 1800mHz0. Due to the symmetrical arrangement of the impellers and the cross flow channels in the pump casing, as shown in Figure 2, it is larger in size than a segmented multi-stage pump of the same performance, has a complex casting process, and has high requirements for the positioning of the pump cover and the pump body. When the pressure is high, it is difficult to seal the joint surface between the pump cover and the pump body.