Installation method of multi-stage booster pump

The installation of a multi-stage booster pump usually involves multiple steps. The following is a detailed installation process:

1. Preparation before installation

Check the equipment: Before installation, check the integrity of the multi-stage booster pump and its supporting equipment (such as motors, electric control cabinets, etc.) to ensure that there are no damaged or missing parts.

Determine the location: According to actual needs, choose a location close to the water source and convenient for operation and maintenance as the installation point. Generally, the multi-stage booster pump should be located near the liquid supply source to facilitate the suction and pumping of liquids.

2. Installation foundation

Prepare the foundation: Prepare a flat and solid foundation according to the size and weight of the multi-stage booster pump. This foundation should be strong enough to withstand the weight and vibration of the pump.

Install the pump body: Place the multi-stage booster pump on the foundation and calibrate it to ensure that the pump body is level and stable. If needed, you can raise the pump body by 30-40 mm to facilitate filling with cement slurry.

Fix the pump body: Put on the anchor bolts and fill with cement mortar. After the cement dries up (usually 3-5 days), recalibrate the pump body and tighten the nuts of the anchor bolts.

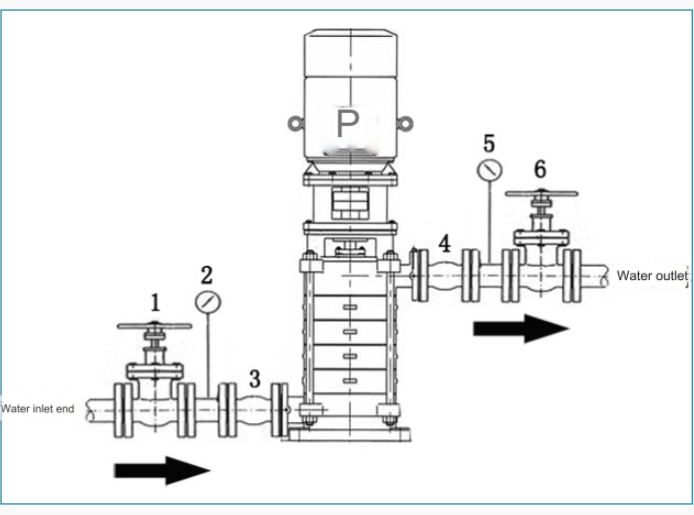

3. Install pipelines

Inlet and outlet pipelines: Install the inlet and outlet pipelines of the multi-stage booster pump according to the design requirements and actual site conditions. The inlet pipeline should be connected to the liquid supply source, and the outlet pipeline should be connected to the system that needs to be pressurized. The pipeline connection should be tight and leak-free.

Support pipeline: For multi-stage vertical centrifugal pumps, the inlet and outlet pipelines should have their own supports, and the pump flange should not be subjected to excessive pipeline weight.

Filter: It is best to install a filter on the inlet pipeline to prevent impurities from entering the impeller. The effective area of the filter should be 3-4 times the area of the inlet pipe to ensure the free flow of liquid.

4. Install electrical equipment

Motor installation: Install the corresponding motor according to the model and specifications of the multi-stage booster pump. Ensure that the connection between the motor and the pump body is correct.

Electric control cabinet: Install the electric control cabinet and connect it. Ensure that the wiring is correct and ground it to ensure electrical safety.

5. Install accessories and attachments

Pressure switch: Install a pressure switch as needed to control the start and stop of the multi-stage booster pump.

Valve: Install a regulating valve on each inlet and outlet pipeline to adjust the flow and pressure. At the same time, install a pressure gauge near the pump outlet to check the operating status of the pump at any time.

6. Startup and commissioning

Check the propeller direction: Before starting the motor, check whether the propeller rotates in the correct direction.

Start the motor: Start the motor and gradually increase the speed. Observe the operation of the pump to ensure that all parameters are normal.

Adjust parameters: Adjust parameters such as pressure and flow according to actual needs to achieve the best operating state.

7. Maintenance

Regular inspection: Regularly check the operation and various parameters of the multi-stage booster pump.

Cleaning the filter: Regularly clean the filter on the inlet pipeline to prevent clogging.

Replace parts: Replace damaged or aging parts in time to ensure the normal operation of the pump.