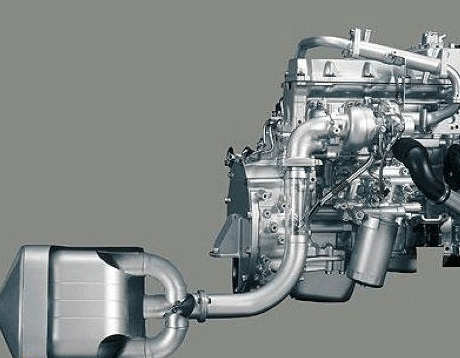

Installation of stationary diesel engine exhaust system

The installation of a fixed diesel engine exhaust system is a key link, which directly affects the operating efficiency and safety of the diesel engine. The following are some important precautions and steps for the installation of a fixed diesel engine exhaust system:

1. Preparation before installation

Design planning: According to the model, power and working environment of the diesel engine, reasonably design the layout and size of the exhaust system. Ensure that the exhaust system can meet the exhaust needs of the diesel engine and comply with relevant safety regulations and environmental protection requirements.

Material selection: Select high-quality materials that are resistant to high temperature, corrosion and wear to make exhaust pipes and accessories. Commonly used materials include stainless steel, cast iron, etc.

Tool preparation: Prepare the tools and equipment required for installation, such as wrenches, screwdrivers, welding equipment, etc.

2. Installation steps

Determine the installation location: Install the exhaust system away from flammable, explosive items and crowded areas. Ensure that the exhaust pipe has enough space for thermal expansion and gas flow.

Install the exhaust pipe:

Connect the exhaust pipe to the exhaust port of the diesel engine according to the design plan. Note that the connection of the pipe should be tight and leak-free, and flange connection, welding, etc. can be used.

Try to avoid using too many elbows and too long pipes to reduce exhaust resistance and back pressure. If elbows must be used, elbows with large arc transitions should be selected to reduce resistance.

Ensure that the installation position of the exhaust pipe is stable and reliable to avoid vibration and displacement during operation.

Install muffler: Install muffler at the appropriate position of the exhaust system to reduce exhaust noise. The selection of muffler should be determined according to the exhaust volume and noise requirements of the diesel engine.

Install insulation material: In order to prevent high-temperature exhaust pipes from causing heat radiation and heat damage to the surrounding environment and equipment, insulation materials should be wrapped on the outside of the exhaust pipe.

Inspection and debugging: After installation, the exhaust system should be fully inspected to ensure that there is no leakage and looseness. Then conduct trial operation and debugging to check whether the operating condition and noise level of the exhaust system meet the requirements.

3. Installation precautions

Ensure sealing: All joints of the exhaust system must be tight and leak-free to prevent exhaust gas leakage from causing harm to the environment and personnel.

Prevent thermal fatigue: The exhaust pipe is prone to thermal expansion and deformation at high temperatures, so measures should be taken to reduce thermal stress concentration to prevent thermal fatigue and cracking.

Consider safety: The exhaust system should be away from flammable and explosive items and crowded areas to prevent fire or scalding accidents. At the same time, the exhaust pipe should avoid contact with electrical facilities such as wires and cables to prevent electrical fires.

Comply with environmental protection requirements: The design and installation of the exhaust system should comply with national and local environmental protection requirements to reduce the impact of exhaust emissions on the environment.

The installation of a fixed diesel engine exhaust system requires comprehensive consideration of multiple factors to ensure its safe, efficient and environmentally friendly operation.