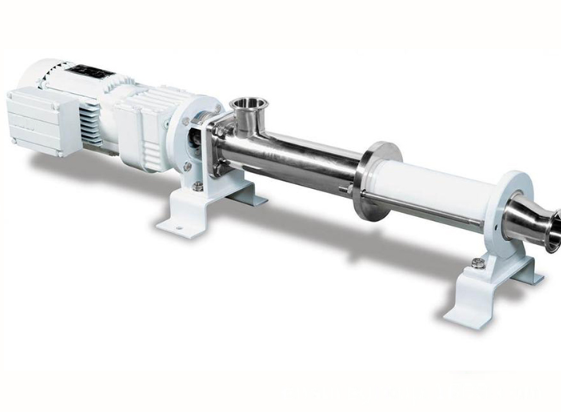

Introduction to the suction method of screw pump

The screw pump is a fluid conveying equipment widely used in the industrial field. Its suction method is crucial to the performance and use effect of the pump. The following is a detailed introduction to the suction method of the screw pump:

1. Main suction method

Single suction: The medium is sucked in from one end of the screw and then discharged from the other end. This suction method has a relatively simple structure and is suitable for conveying relatively clean fluids with moderate viscosity.

Double suction: The medium is sucked in from both ends of the screw at the same time and discharged from the middle. The design of the double suction screw pump enables it to have better performance when handling high viscosity, particle-containing or corrosive fluids.

In addition, there is a more common classification method, which is to divide the suction method of the screw pump into axial suction and mirror suction (or other non-axial suction methods). Under this classification:

Axial suction: The fluid enters the pump body along the axial direction of the pump, which is consistent with the rotation direction of the screw. This suction method helps the fluid to enter the pump body smoothly, reduces the resistance of the fluid during the suction process, and thus improves the efficiency and stability of the pump. The axial suction method is a commonly used suction method for screw pumps and is suitable for a variety of fluid delivery scenarios.

Mirror suction (or other non-axial suction methods): In some special cases, screw pumps can also use other suction methods such as mirror suction. These suction methods are usually customized according to specific usage scenarios and needs to meet specific fluid delivery requirements.

2. The impact of suction method on screw pump performance

Efficiency: The axial suction method reduces the resistance of the fluid during the suction process, allowing the fluid to enter the pump body more smoothly, thereby improving the pump's delivery efficiency.

Stability: The axial suction method makes the flow of the fluid in the pump body more uniform, reducing the vibration and noise of the pump body caused by unstable fluid flow.

Scope of application: Different suction methods are suitable for different fluid delivery scenarios. For example, the axial suction method is suitable for the delivery of high-viscosity, particle-containing or corrosive fluids; while other methods such as mirror suction may be more suitable for certain special occasions.

3. Selection suggestions

When choosing the suction method of the screw pump, it is necessary to make a comprehensive consideration based on the specific usage scenarios and needs. Here are some suggestions:

Understand the fluid characteristics: First, you need to understand the characteristics of the fluid being transported, including viscosity, particle content, corrosiveness, etc. These characteristics will directly affect the choice of suction method.

Consider the performance requirements of the pump: Select the appropriate suction method according to the performance requirements of the pump, such as delivery efficiency, stability, noise, etc.

Refer to the manufacturer's recommendations: When choosing the suction method, you can refer to the recommendations of the screw pump manufacturer. Manufacturers usually provide users with appropriate suction method recommendations based on product design and usage experience.

The suction method of the screw pump has an important impact on its performance and use effect. When choosing the suction method, it is necessary to comprehensively consider factors such as fluid characteristics, pump performance requirements, and manufacturer recommendations to ensure the normal operation and efficient operation of the screw pump.