Lubrication system of centrifugal pump

The lubrication system of a centrifugal pump is crucial to the normal operation of the pump. It is mainly responsible for ensuring the lubrication and cooling of the pump shaft and bearings, thereby reducing the wear and friction of the pump, extending the service life of the pump, and improving the operating efficiency of the pump. The following is a detailed analysis of the lubrication system of a centrifugal pump:

1. The role of the lubrication system

Lubrication: Ensure good lubrication between the pump shaft and the bearing, reduce friction and wear, and protect the bearings and journals.

Cooling: Through the circulation of lubricating oil, the heat generated by friction between the bearings and journals is taken away to prevent damage caused by overheating.

Cleaning: The lubricating oil can take away impurities and particles on the surface of the bearings and journals to maintain their cleanliness.

Sealing: In some cases, the lubricating oil can also play a sealing role to prevent external impurities from entering the bearings.

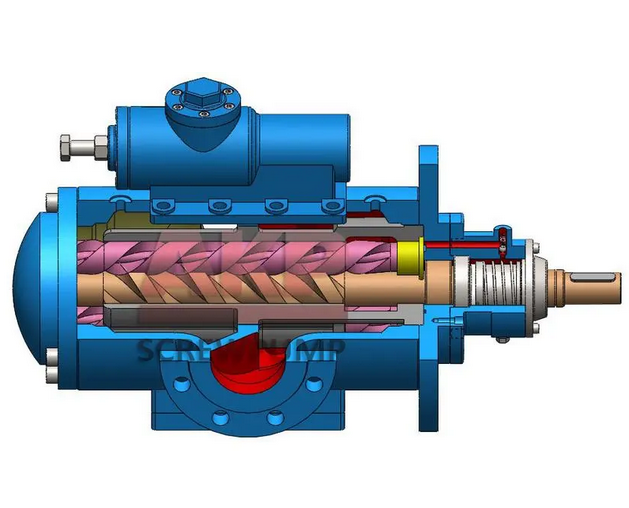

2. Composition of the lubrication system

The lubrication system of a centrifugal pump is mainly composed of the following parts:

Lubricating oil tank: used to store lubricating oil to ensure that the system has sufficient lubricating oil supply.

Oil pump: Provides continuous lubrication for bearings and journals by outputting oil through work.

Oil cooler: Cools the circulating lubricating oil to prevent the lubricating oil from failing due to excessive temperature.

Pressure switch: monitors oil pressure to ensure that the pump shaft and bearings are adequately lubricated. When the oil pressure is insufficient, it can sound an alarm or automatically shut down.

Filter element: filter impurities and particles in the lubricating oil to maintain the cleanliness of the lubricating oil.

3. Maintenance of the lubrication system

In order to ensure the normal operation of the centrifugal pump lubrication system, regular maintenance and inspection are required:

Regularly check the quality and oil level of the lubricating oil: ensure that the lubricating oil is not deteriorated or contaminated, and the oil level remains within the normal range.

Regularly replace the lubricating oil: regularly replace the new lubricating oil according to the use of the equipment and the performance indicators of the lubricating oil.

Clean and replace the filter element: regularly clean or replace the filter element to prevent the filter element from clogging and affecting the filtering effect of the lubricating oil.

Check the oil pump and pressure switch: ensure that the oil pump is working properly and the pressure switch can accurately monitor the oil pressure and sound an alarm.

Pay attention to the ambient temperature: in places where the ambient temperature is too low, it is necessary to select a lubricating oil with a low freezing point, and consider adding heating equipment to prevent the lubricating oil from solidifying.

4. Choice of lubrication method

The lubrication methods of centrifugal pumps are mainly oil lubrication and grease lubrication. For medium and light load centrifugal pumps, oil lubrication or grease lubrication can be used; for heavy load centrifugal pumps, oil lubrication should be used. In addition, for centrifugal pumps with large shaft power (such as above 2000kW), sliding bearings and pressure oil lubrication systems should also be considered.