Magnetic gear pump leak-free design

The leakage-free design of the magnetic gear pump is one of its core technologies, which is mainly reflected in the following aspects:

1. Principle of magnetic transmission

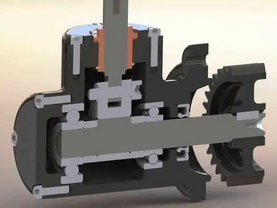

Magnetic coupler: The magnetic gear pump uses a magnetic coupler to transmit power. The outer magnetic rotor at the driving end is driven to rotate by the motor, and the inner magnetic rotor and impeller inside the pump are driven to rotate together through the action of the magnetic field to achieve the suction and discharge of liquid. This design avoids the shaft seal structure in traditional mechanical transmission and fundamentally eliminates the possibility of leakage.

No physical contact: There is no physical contact between the driving end and the working end of the magnetic transmission gear pump, and power transmission is achieved through the action of the magnetic field. This design avoids friction and wear in traditional mechanical transmission, improves transmission efficiency and reliability, and also prevents leakage problems caused by wear of seals.

2. High-performance magnetic materials

Rare earth permanent magnet materials: Modern magnetic pumps usually use high-performance rare earth permanent magnet materials, such as neodymium iron boron, etc. These materials have strong magnetic force, which can achieve efficient power transmission even in a very small space, further ensuring the reliability of leakage-free.

3. Optimized fluid dynamics design

Internal structure design: The internal design of the magnetic gear pump optimizes the flow path of the fluid, reduces the impact of the liquid on the impeller and internal wear, thereby extending the service life of the pump. At the same time, this design also helps to improve the sealing performance of the pump and prevent leakage.

4. Sealing structure

Static seal: The pump shaft of the magnetic gear pump is changed from a dynamic seal to a closed static seal, which completely avoids the possibility of the medium leaking to the external environment through the shaft seal. This static seal structure not only improves the sealing performance, but also simplifies the sealing structure and reduces maintenance costs.

5. Protection measures

Overload protection: When the driven part of the magnetic transmission is running under overload or the rotor is stuck, the main and driven parts of the magnetic transmission will automatically slip off to protect the machine pump. This design avoids damage to the pump body and leakage problems caused by overload.

6. Application and advantages

Wide application: The leakage-free design of the magnetic gear pump makes it widely used in many industries such as chemical, pharmaceutical, electronic, and food, especially in fields with strict requirements for environmental protection and production safety.

Improve safety: When handling flammable, explosive or toxic media, leakage-free pumps significantly improve the safety of the production process.

Reduce maintenance costs: Since there is no wear of dynamic sealing elements, the maintenance cost of magnetic gear pumps is much lower than that of traditional pumps.

In summary,the leakage-free design of magnetic gear pumps is achieved through a variety of measures such as magnetic transmission principle, high-performance magnetic materials, optimized fluid dynamics design, static sealing structure and overload protection. This design not only improves the sealing performance and reliability of the pump, but also reduces maintenance costs and production safety risks.