Maintenance costs of diesel pumps

The maintenance cost of a diesel pump is a relatively complex concept. It is affected by many factors, including the type, brand, frequency of use, working environment, maintenance cycle, and maintenance content of the diesel pump. The following is an analysis of some of the main aspects of the maintenance cost of a diesel pump:

1. Maintenance content

Regular maintenance: Including changing the engine oil, filter, etc., these are basic maintenance measures to keep the diesel pump running normally. The cost of routine maintenance is relatively low, but the frequency is high, and it is an important part of the maintenance cost.

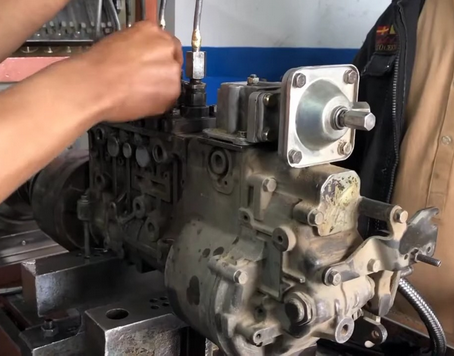

Fault repair: When a diesel pump fails, it needs to be repaired or replaced accordingly. The cost of fault repair depends on the type and severity of the fault, and may include labor costs, parts costs, etc.

Professional testing: Regular professional testing of diesel pumps can detect potential problems in time and take measures to avoid failures. The cost of professional testing includes testing fees and equipment usage fees.

2. Influencing factors

Frequency of use: The higher the frequency of use of the diesel pump, the faster it wears and ages, and the maintenance cost increases accordingly.

Working environment: Harsh working environments (such as high temperature, humidity, dust, etc.) will accelerate the wear and aging of diesel pumps and increase maintenance costs.

Maintenance cycle: A reasonable maintenance cycle can ensure that the diesel pump operates in the best condition, reduce the possibility of failure, and thus reduce maintenance costs.

Maintenance quality: High-quality maintenance can extend the service life of the diesel pump and reduce the number of failures, thereby reducing long-term maintenance costs.

3. Strategies to reduce maintenance costs

Strengthen daily maintenance: By strengthening daily maintenance, small problems can be discovered and handled in a timely manner, avoiding small problems from turning into big problems, thereby reducing maintenance costs.

Reasonable arrangement of maintenance cycles: According to the use and working environment of the diesel pump, the maintenance cycle is reasonably arranged to ensure that the diesel pump operates in the best condition.

Select high-quality accessories: During the maintenance process, selecting high-quality accessories can ensure the quality of maintenance, extend the service life of the diesel pump, and thus reduce long-term maintenance costs.

Strengthen training and management: Provide professional training for maintenance personnel to improve their skill level; at the same time, strengthen equipment management to ensure the normal operation of equipment and reduce the possibility of failures.