Maintenance of mechanical seal of submersible pump

The maintenance of the mechanical seal of the submersible pump is a key link to ensure the normal operation of the submersible pump. The following are the detailed steps and precautions for the maintenance of the mechanical seal of the submersible pump:

1. Inspection and diagnosis

Appearance inspection:

Check whether there is obvious damage, wear or oil leakage on the outside of the mechanical seal.

Observe the smoothness and cleanliness of the sealing surface to ensure that there are no impurities or scratches.

Performance test:

Through the running test, observe whether the submersible pump has abnormal vibration, noise or leakage during operation.

Use instruments to detect the insulation resistance and current of the submersible pump to determine whether the electrical part is normal.

2. Disassembly and cleaning

Power off and drainage:

Before disassembly, be sure to cut off the power supply of the submersible pump and drain the water in the pump body.

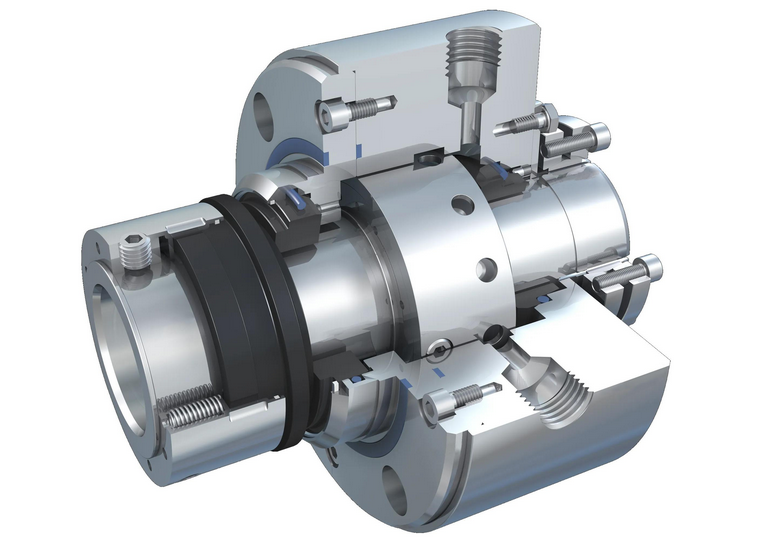

Disassembly of mechanical seal:

According to the structural characteristics of the submersible pump, gradually remove the bolts, bearings and other components on the pump body until the mechanical seal is exposed.

Carefully remove the mechanical seal assembly to avoid damage to other components.

Clean parts:

Use special cleaning agents or clean water to clean the various components of the mechanical seal to ensure that there are no oil stains, dirt and impurities on the surface.

Inspect and clean the sealing surface to ensure that it is smooth and scratch-free.

3. Repair and Replacement

Replacement of worn parts:

Check whether the dynamic ring, static ring, sealing ring and other parts of the mechanical seal are seriously worn or aged.

If wear or aging is found, replace the parts of the same model and specification in time.

Adjust the seal gap:

According to the use requirements of the submersible pump, adjust the gap between the dynamic ring and the static ring to ensure good sealing effect.

Install a new seal:

Install the new mechanical seal assembly to the pump body in the reverse order of disassembly.

Pay attention to the direction and position during installation to ensure that the sealing surface fits tightly.

4. Testing and Debugging

Static test:

Without power on, manually turn the impeller of the submersible pump to check whether the mechanical seal has leakage or abnormality.

Dynamic test:

Turn on the power and let the submersible pump run for a period of time under no-load condition to observe whether there is leakage or abnormal sound.

If there is no abnormality, the load can be gradually increased for testing.

5. Precautions

Safety first:

During the maintenance process, be sure to comply with the safety operating procedures to ensure personal and equipment safety.

Professional maintenance:

If you have no relevant experience or skills, it is recommended to ask professionals to repair or replace the mechanical seal.

Regular inspection:

Maintain and inspect the submersible pump regularly to find and solve problems in time to ensure long-term stable operation of the submersible pump.

Select high-quality accessories:

When replacing mechanical seals and other parts, high-quality accessories produced by regular manufacturers should be selected to improve the reliability and service life of the equipment.