Material selection for magnetic pump isolation sleeve

There are many choices of materials for magnetic pump isolation sleeves, which mainly depend on the use environment of the pump and the characteristics of the medium being transported. The following are common materials and characteristics of magnetic pump isolation sleeves:

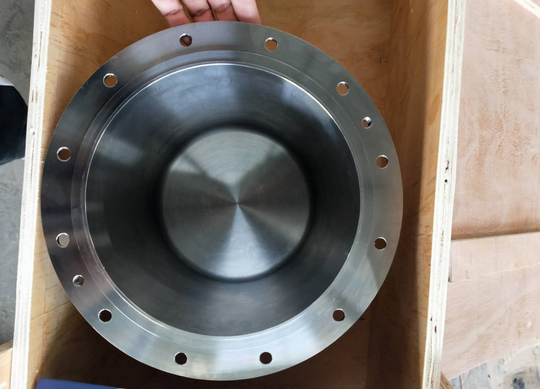

1. Metal materials

316L stainless steel:

It is a commonly used stainless steel material with good corrosion resistance and mechanical properties.

It is suitable for the transportation of a variety of corrosive media, but when working in a high-speed alternating magnetic field, it will produce certain eddy current losses.

Titanium alloy:

It has excellent performance, high strength and good corrosion resistance.

It is suitable for occasions with higher requirements, but the price is relatively high.

Hastelloy alloy:

It has high resistivity and high strength, which can effectively reduce eddy current losses.

However, due to the high cost of materials, its wide application is limited.

Austenitic stainless steel:

It is also a common metal material with good corrosion resistance and mechanical properties.

It is widely used in magnetic pump isolation sleeves.

2. Non-metallic materials

Engineering plastics:

If the working pressure is not high, high-strength engineering plastics can be used as isolation sleeve materials.

Engineering plastics have light weight and good corrosion resistance, but relatively poor high temperature resistance.

Carbon fiber composite materials:

Carbon fiber materials are non-magnetic, non-conductive, and have extremely high strength and good corrosion resistance.

It can be used in high-temperature and high-pressure magnetic pumps, and has a long service life, fatigue resistance, and aging resistance.

The strength of the carbon fiber isolation sleeve is equivalent to that of titanium alloy, and there is no eddy current loss. It is a perfect substitute for metal, plastic, and ceramic isolation sleeves.

Ceramic:

The eddy current loss of the isolation sleeve of ceramic material is almost zero, but the ceramic material is fragile and has poor mechanical shock and thermal shock resistance.

It is complex to process, expensive, and difficult to assemble, so it has not been widely used.

Selection principle

When selecting the material of the isolation sleeve of the magnetic pump, the following factors need to be considered:

Corrosiveness of the medium: Select suitable corrosion-resistant materials according to the corrosiveness of the medium being transported.

Working pressure and temperature: Consider the influence of working pressure and temperature on material properties, and select materials that can withstand the corresponding pressure and temperature.

Eddy current loss: Try to choose non-ferromagnetic materials with high resistivity to reduce eddy current loss.

Cost: Consider factors such as material cost, processing cost, and service life, and select cost-effective materials.