Method for balancing the axial force of water pump

There are many ways to balance the axial force of a water pump. Depending on the type of water pump (such as a single-stage pump or a multi-stage pump) and the specific design, different strategies can be used to effectively balance the axial force. The following are some common methods for balancing the axial force of a water pump:

1. Methods for balancing the axial force of a single-stage pump

Double-sided water inlet:

By designing the impeller to have water inlet on both sides, some or all of the axial force can be balanced. This method is simple and effective, and is particularly suitable for certain specific types of single-stage pumps.

Opening a balancing hole or installing a balancing pipe:

Opening a balancing hole or installing a balancing pipe at the rear cover of the impeller to reduce the pressure difference on both sides of the impeller, thereby balancing the axial force. There are generally 4 to 6 balancing holes, and the total area is five times the area of the sealing surface gap. However, this method may cause an increase in the volume loss of the pump and reduce the overall efficiency of the pump.

Setting a back blade:

A back blade is installed on the impeller outlet cover. The back blade can generate a force in the opposite direction of the axial force, thereby balancing part of the axial force. At the same time, the back blade can also play a certain role in protecting the shaft seal.

Installing a thrust bearing:

For the remaining axial force, it can be borne by installing a thrust bearing. However, it should be noted that thrust bearings can only balance small axial forces, so they are more suitable for small pumps.

2. Methods for balancing the axial force of multistage pumps

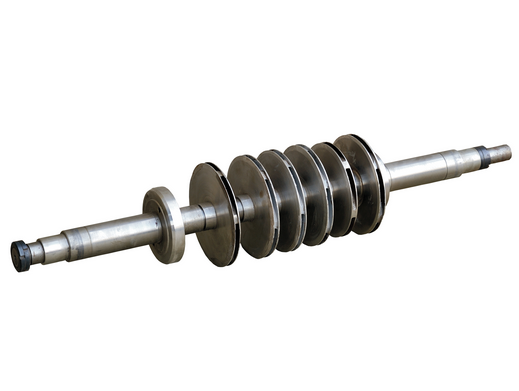

Impeller symmetrical arrangement:

By arranging the impellers of multistage pumps in a relative or symmetrical manner, the generation of axial force can be reduced. This method is more common in multistage pumps.

Balancing disc device method:

The balancing disc is a commonly used axial force balancing device in multistage pumps. It is located behind the last stage of the impeller of the pump, and generates a balancing force opposite to the axial force through the pressure difference between the front and rear chambers of the balancing disc, thereby achieving a balancing effect. The balancing disc structure can automatically adjust its variable clearance to adjust the balancing force, and the axial force of the rotor can be completely balanced without the assistance of an external thrust bearing.

Balancing drum and bidirectional thrust bearing method:

This method combines the advantages of balancing drums and bidirectional thrust bearings, and balances the axial force of multistage pumps through the balancing effect of the balancing drum and the supporting effect of the bidirectional thrust bearing.

The method of using a balancing drum with a balancing disc:

This method uses both balancing drums and balancing discs in a multistage pump to balance the axial force through their synergistic effect. This method is usually suitable for multi-stage pumps with large axial forces or requiring higher balancing accuracy.