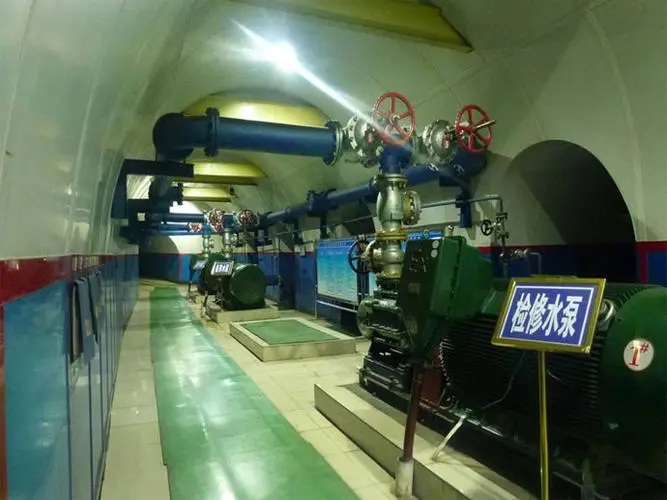

Mine Dewatering Pump Characteristics

Mine drainage pumps are an indispensable and important equipment in the mining industry. Their characteristics are directly related to the safe production and drainage efficiency of mines. The following are the main characteristics of mine drainage pumps:

1. High efficiency: Mine drainage pumps are usually designed with high efficiency and a wide performance range to meet the drainage needs of different mines. Its flow range is wide. For example, the flow range of high-pressure drainage pumps for coal mines can reach 80m³/h~2200m³/h, and the head range is 100~1700m, which can adapt to various complex working conditions.

2. High power: Since the drainage volume of mines is usually large, mine drainage pumps need to have higher power. Its power range ranges from 55kW to 4000kW to meet the needs of different drainage volumes.

3. Multiple voltage options: Mine drainage pumps support multiple voltages, such as 380V, 660V, 1140V, 3kV, 6kV, 10kV, etc., to meet the needs of different mine power systems.

4. Compact structure: Mine drainage pumps usually adopt a compact structural design, such as 6KV mine drainage electric pumps, which have a compact structure, small size, light weight, and are easy to install and maintain.

5. Stable operation: The operation performance of mine drainage pumps is stable and can work continuously for a long time. They use advanced sealing technology and cooling system to ensure that the pump can operate stably even in harsh environments.

6. Easy installation: There are various installation methods for mine drainage pumps, such as vertical, horizontal, inclined, etc., and the appropriate installation method can be selected according to the actual working conditions. At the same time, the pump body material usually adopts corrosion-resistant materials such as stainless steel or tin bronze to extend the service life.

7. Intelligent control: Modern mine drainage pumps have realized intelligent control and have remote monitoring and automatic detection functions. By installing monitoring equipment such as temperature measuring devices, the internal temperature of the motor winding can be monitored in real time to ensure the safe operation of the pump.