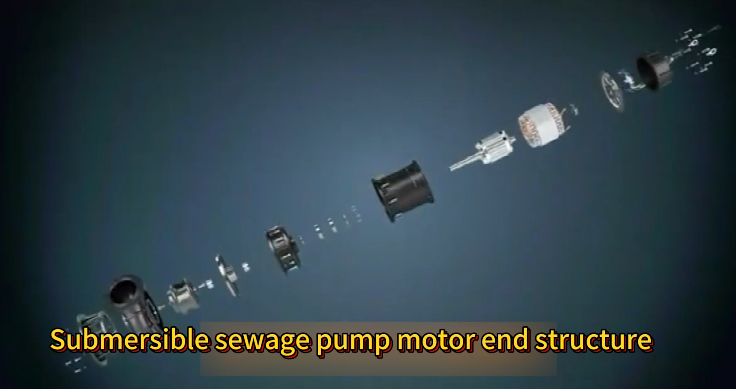

Motor end structure of submersible sewage pump

The motor end structure of the submersible sewage pump is its core component, which is mainly responsible for providing power and ensuring the stable operation of the pump in an underwater environment. The following is a detailed analysis of the motor end structure of the submersible sewage pump:

1. Motor type and position:

The motor usually adopts a three-phase squirrel cage induction vertical motor, which is located on the upper part of the electric pump.

The insulation grade is usually Class B or higher to meet the safety requirements of underwater work.

2. Motor connection and cable:

Motors of 4KW and below use star connection, while motors of 5.5KW and above use triangle connection.

The cable used for the motor is YZW type or other models with the same performance. It is a medium-sized rubber four-core cable, which includes a green and yellow two-color grounding wire to ensure safe use.

3. Motor cooling method:

The heat energy of the motor is cooled by external water, so the submersible sewage pump needs to be completely immersed in water to ensure good cooling conditions.

4. Sealing structure:

The sealing structure of the motor end includes two parts: dynamic seal and static seal.

The dynamic seal usually adopts an integral sealing box structure or a double-end bellows bulk seal. The oil chamber of the mechanical seal is filled with No. 5 to No. 10 mechanical oil for lubrication and heat dissipation of the mechanical seal.

The static seal is located at the joint of the stopper of each part of the electric pump, and an "O" type oil-resistant rubber sealing ring is used to achieve a good sealing effect.

5. Motor protection and safety monitoring:

The motor stator is made of high insulation grade material and is equipped with overheating and overload protection elements to ensure that the motor is protected in time under abnormal conditions.

Some submersible sewage pumps are also equipped with two-stage seal monitoring. If any seal leaks, an alarm signal can be issued to detect and deal with the leakage problem in time.

In summary, the motor end structure of the submersible sewage pump has been carefully designed to ensure the efficient operation of the motor and its safety and reliability in the underwater environment.