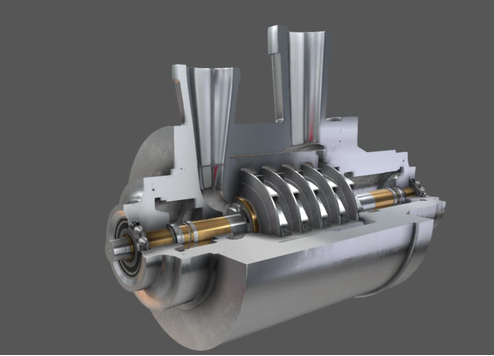

Multistage centrifugal pump impeller symmetrical arrangement

The symmetrical arrangement of multi-stage centrifugal pump impellers is an effective axial force balance method, which is especially important in the design of multi-stage centrifugal pumps. The following is a detailed analysis of the symmetrical arrangement of multi-stage centrifugal pump impellers:

1. Principle of symmetrical arrangement of impellers

The symmetrical arrangement of impellers in multi-stage centrifugal pumps mainly refers to installing each two impellers symmetrically on the same pump shaft in opposite directions so that the axial forces generated by each two impellers cancel each other out. This arrangement can significantly reduce the axial force generated by the pump during operation, thereby improving the stability and operating efficiency of the pump.

2. Advantages of symmetrical arrangement of impellers

The axial force balance effect is good: through the forward and reverse symmetrical arrangement of the impellers, the axial forces generated by each two impellers can offset each other, thereby greatly reducing the axial force of the entire pump and improving the operating stability of the pump.

Reduce vibration and noise: The balance of axial force helps reduce vibration and noise during pump operation and prolongs the service life of the pump.

Improve pump efficiency: Due to the reduction of axial force, the pump runs more smoothly and can more effectively convert mechanical energy into pressure energy and kinetic energy of the liquid, thereby improving pump efficiency.

3. Application scenarios of symmetrical arrangement of impellers

Large flow centrifugal pump: For centrifugal pumps that need to handle large flow of liquid, the symmetrical arrangement of the impeller can better balance the axial force and ensure the stable operation of the pump.

High temperature and high pressure media: Under severe working conditions such as high temperature and high pressure, the symmetrical arrangement of the impeller can reduce the vibration and wear of the pump and improve the reliability and service life of the pump.

Systems sensitive to axial force: In some systems sensitive to changes in axial force, such as precision instrument cooling systems, nuclear power plant cooling systems, etc., the symmetrical arrangement of the impellers can ensure stable operation of the system.

4. Precautions

Impeller machining accuracy: The symmetrical arrangement of the impeller requires the impeller to have high machining accuracy and assembly accuracy to ensure effective offset of axial force.

Seal ring wear: Since the manufacturing and wear conditions of the seal rings on both sides of the impeller are inevitably different, there will also be errors in the processing of the impeller, so the pressure distribution on both sides of the impeller is difficult to be completely symmetrical. Therefore, when the impeller is arranged symmetrically, it is necessary to pay attention to the wear of the sealing ring and take corresponding measures to compensate.

Pump casing structural complexity: The symmetrical arrangement of the impeller will increase the structural complexity of the pump casing, thereby increasing manufacturing costs and maintenance difficulty. Therefore, factors such as cost, performance, and ease of maintenance need to be taken into consideration when designing.