Performance comparison between horizontal screw pump and vertical screw pump

Horizontal screw pumps and vertical screw pumps have their own characteristics in performance. The following is a detailed comparison of their performance:

1. Structural characteristics

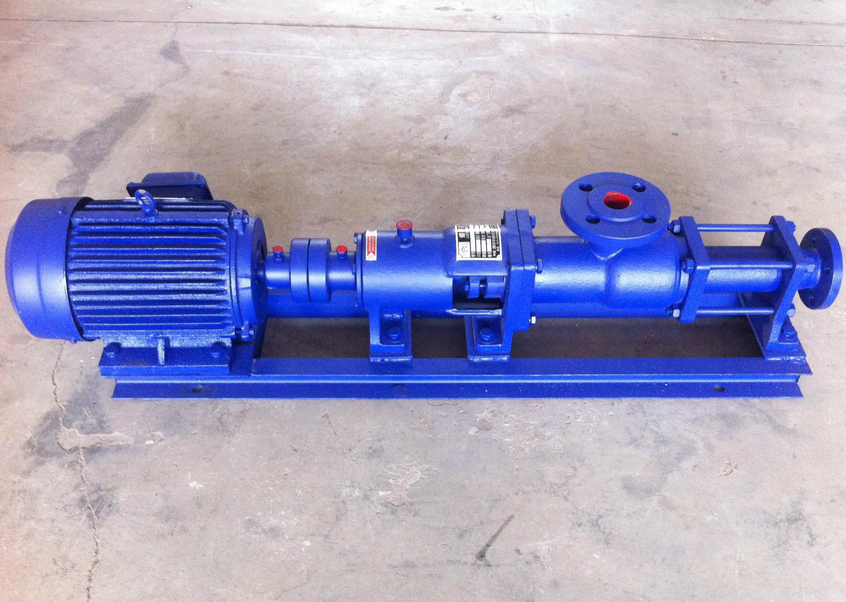

Horizontal screw pump

The structure is relatively mature, the parts are highly versatile, and it is easy to repair and replace parts.

The horizontal installation method makes the center of gravity of the pump lower, the operation is stable, and the impact of vibration on equipment and pipelines is reduced.

Vertical screw pump

The structure is compact and occupies a small area. It is particularly suitable for places with limited space, such as basements, cabins, etc.

It is usually equipped with an independent support structure and base to ensure the stability of the pump during operation.

The vertical installation method makes it taller, but occupies less horizontal space.

2. Flow and pressure

Horizontal screw pump

Under normal operating conditions, it can provide a relatively stable flow and pressure output, which is suitable for occasions with strict requirements on flow and pressure.

Vertical screw pump

The flow rate is proportional to the speed, and the flow rate can be adjusted by adjusting the speed.

Pressure generation is related to the "stator" spiral lead, which can withstand higher pressure and is suitable for some processes with higher pressure requirements.

3. Self-priming ability and sealing performance

Horizontal screw pump

The self-priming ability is relatively strong, but the specific performance may vary depending on the model and manufacturing differences.

The pressure at the sealing part is relatively small, the service life of the seal is long, and it is easier to replace.

Vertical screw pump

It has the characteristics of self-priming, which can self-prime the liquid medium through the pipeline, and the height can reach a certain range (such as 6~8.5 meters).

The sealing part is under great pressure, and high-quality seals need to be selected to ensure the sealing performance of the pump.

4. Operation and maintenance

Horizontal screw pump

It runs smoothly, with low noise and low vibration, and has little impact on equipment and pipelines.

Maintenance and maintenance are relatively easy, and the operator can perform maintenance and replace parts in a more comfortable position.

Vertical screw pump

It also runs smoothly and has low vibration, but due to its vertical installation method, special tools and equipment may be required when performing maintenance and replacing parts.

Maintenance and overhaul are also relatively convenient, but it is necessary to pay attention to regular inspection of the verticality and stability of the pump to prevent the pump from tilting or shaking during operation.

5. Medium adaptability

Horizontal screw pump

It is suitable for conveying various media without solid particles, such as lubricating oil, cooling water, etc.

It can also be used to convey multiphase media containing tiny solid impurities, but it may be necessary to select the appropriate pump type and material according to the characteristics of the medium.

Vertical screw pump

It can convey media containing suspended soft and hard solid particles and long fibers (liquid, solid, and gas phases).

When conveying liquids containing solid particles or impurities, the vertical structure of the vertical screw pump can reduce the deposition of impurities in the pump and reduce the risk of blockage.

In summary, horizontal screw pumps and vertical screw pumps have their own advantages in performance. The choice of which type of pump depends mainly on the specific application scenario and needs. When purchasing, it is recommended to make a comprehensive consideration based on actual needs and choose the most suitable pump type.