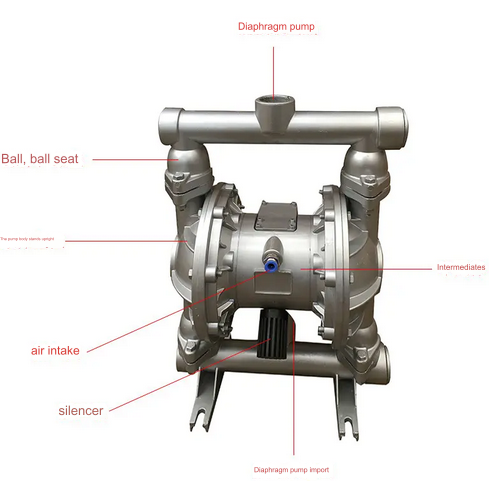

Pneumatic diaphragm pump parts

A pneumatic diaphragm pump is a pump device that uses compressed air to drive the diaphragm for liquid transportation. Its parts mainly include the following parts:

1. Pneumatic motor

Composition: The pneumatic motor is mainly composed of three parts: the motor body, the main valve, and the reversing valve.

Function: This part is a device that converts the energy of compressed air into the kinetic energy of reciprocating motion, provides power for the diaphragm pump, and is the main component of the diaphragm pump.

2. Fluid cover

Function: Combined with the motor body (or air cover) to form a cavity, which is used to accommodate the diaphragm and other components and constitute the working space of the pump.

3. Diaphragm assembly

Composition: The diaphragm assembly includes a diaphragm connecting rod, a diaphragm gasket, a diaphragm bolt and corresponding O-rings, a diaphragm, etc.

Function: The diaphragm separates the cavity into an air cavity and a flow cavity. The diaphragm assembly reciprocates under the action of the pneumatic motor, so that a pressure difference is formed between the air cavity and the fluid cavity, thereby promoting the flow of liquid.

4. Ball valve assembly

Composition: It consists of a ball, a ball seat, etc. and corresponding O-rings.

Function: It acts as a one-way valve to ensure that the liquid can only flow in one direction in the pump body to prevent backflow.

5. Inlet and outlet pipes

Function: The inlet pipe is used to introduce the liquid to be transported into the pump body, while the outlet pipe discharges the pumped liquid out of the pump body. These two parts only serve as pipes for the fluid to enter and exit the pump body.

6. Muffler

Function: The muffler is used to reduce the noise generated when the pump is working and improve the working environment.

7. Other accessories

In addition to the above main components, the pneumatic diaphragm pump may also include some other accessories, such as intermediate body sealing gaskets, cover plates, cover plate pads, steel slide plates, butterfly O-rings, large aluminum blocks, intermediate value sleeves, auxiliary sliders, auxiliary shaft O-rings, movable plugs, pistons, movable sealing rings, auxiliary shafts, auxiliary shaft sleeves, etc. These accessories also play an important role in the operation of the pump, such as ensuring sealing, reducing wear, and improving pump performance.