Precautions for chemical pumps in extracting medium temperature

When the chemical pump extracts media of different temperatures, special attention should be paid to the following points to ensure the normal operation of the pump and extend its service life:

1. Classification and precautions of medium temperature

Medium with a temperature below 120℃

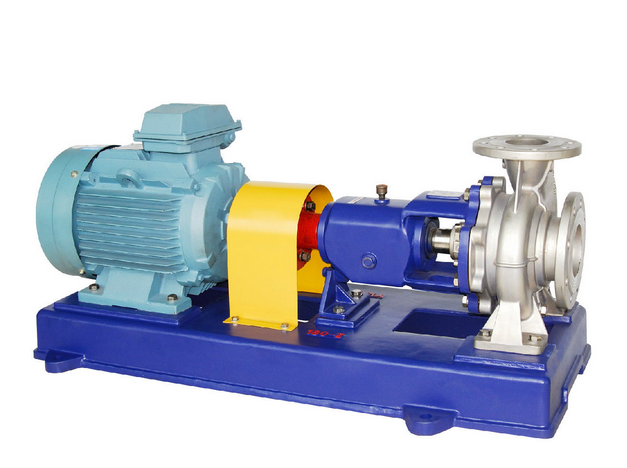

No special cooling system is usually set up: this type of medium can generally be lubricated and cooled by its own medium. For example, chemical pumps, shielded chemical pumps, and fluorine-lined pumps, etc., usually do not require additional cooling measures when the temperature does not exceed their design upper limit.

Handling of special situations: For media that are easy to crystallize or contain particles, a sealing surface flushing pipeline should be provided, and an interface should be left in the design to prevent the medium from accumulating at the sealing surface and causing blockage or damage.

Media above 120℃ and within 300℃

The pump cover is equipped with a cooling chamber: a cooling chamber is set on the pump cover to cool the pump body.

The sealing chamber is connected to the coolant: the sealing chamber should also be connected to the coolant, and a double-end mechanical seal should be equipped to improve the sealing effect.

Coolant selection: When the coolant is not allowed to penetrate into the medium, the method of cooling the medium itself and then connecting it should be adopted, which can be achieved through a simple heat exchanger.

Pump type selection: DFCZ chemical process pumps, GRG high-temperature pipeline pumps, etc. are available on the market. CQB-G high-temperature magnetic pumps can also be used for media within this temperature range.

High-temperature media above 300℃

Comprehensive cooling system: Not only the pump head needs to be cooled, but the suspension bearing chamber should also be equipped with a cooling system.

Pump structure selection: The pump structure is generally a central support form to enhance stability.

Mechanical seal selection: It is better to use a metal bellows type for mechanical seals. Although the price is higher (usually more than 10 times that of ordinary mechanical seals), it can effectively cope with high temperature environments.

2. Other precautions

Temperature monitoring: During operation, the temperature rise of the pump and motor should be checked frequently to ensure that the temperature rise of the bearing does not exceed the allowable range (generally not more than 75℃).

Oil level control: For parts that need lubrication, the oil level should be checked regularly and kept within the specified range. At the same time, new oil should be replaced regularly to keep the oil clean and have a good lubrication effect.

Fault handling: During operation, if abnormal sounds or other faults are found, the machine should be stopped and checked immediately, and the operation can only be continued after the fault is eliminated.

Pump protection: The pump cannot be operated for a long time at a flow rate lower than the design flow rate. If it must be used under this condition, a bypass pipe should be installed on the outlet pipeline to increase the flow rate.