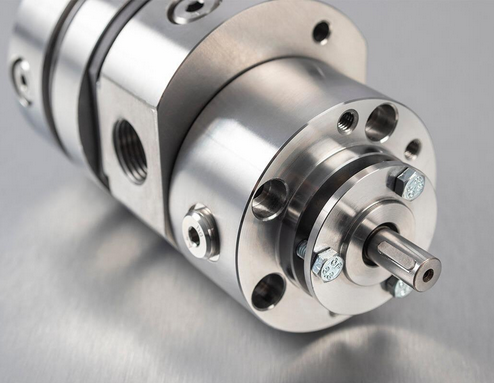

Precision gear pump chemical industry application

Precision gear pumps are also widely used in the chemical industry. Their unique structure and performance advantages make them one of the indispensable fluid conveying equipment in the chemical industry. The following is a specific analysis of the application of precision gear pumps in the chemical industry:

1. Requirements for conveying equipment in the chemical industry

The chemical industry has extremely high requirements for conveying equipment, and the equipment needs to withstand harsh environments such as various chemical corrosion, high temperature and high pressure. At the same time, the special properties of chemical raw materials, such as corrosiveness and volatility, require conveying equipment to have good sealing performance and safety.

2. Advantages of precision gear pumps in the chemical industry

Corrosion resistance:

Precision gear pumps are usually made of corrosion-resistant materials, such as stainless steel, alloys, etc., which can meet the transportation needs of various corrosive media in the chemical industry.

Sealing performance:

Gear pumps have excellent sealing performance, which can effectively prevent leakage and ensure the purity and stability of chemical raw materials during transportation.

Efficient and stable:

Precision gear pumps use advanced gear transmission technology to achieve efficient and stable liquid transportation. Its unique structural design makes the liquid flow inside the pump body smoother, reducing energy loss and pump body vibration.

Diversified applications:

Gear pumps are suitable for the transportation of various liquid media in the chemical industry, such as acids, alkalis, salts, solvents, etc. At the same time, its compact structure and stable operation also make gear pumps occupy an important position in the supporting use of chemical equipment.

3. Specific application scenarios

Chemical raw material transportation:

In the chemical production process, various raw materials need to be mixed and transported in a specific proportion. Precision gear pumps can accurately measure and transport various raw materials to ensure the continuity and stability of chemical production.

Reactor feeding:

The reactors commonly used in chemical production require a stable feeding system. Precision gear pumps can provide precise flow control to ensure that the materials in the reactor are added according to the predetermined proportion and time, thereby improving the reaction efficiency and product quality.

Corrosive medium transportation:

There are a large number of corrosive media in the chemical industry, such as sulfuric acid, hydrochloric acid, etc. Precision gear pumps are made of corrosion-resistant materials and can safely and stably transport these corrosive media to ensure the continuity and safety of the production process.

Circulation system and cooling system:

In some chemical production processes, a circulation system and a cooling system need to be set up to maintain the stability of the reaction temperature and reduce the equipment temperature. As an important part of these systems, precision gear pumps can provide stable flow and pressure control to ensure the normal operation of the system.

In summary, the application of precision gear pumps in the chemical industry is extensive and important. Its corrosion resistance, sealing performance, high efficiency and stability, and diversified applications make gear pumps one of the indispensable fluid conveying equipment in the chemical industry.