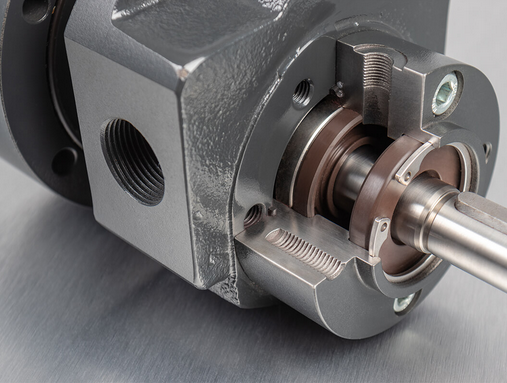

Precision gear pump hydraulic system

The precision gear pump hydraulic system is an important part of the hydraulic system. It mainly relies on the working principle of the gear pump to realize the delivery of liquid and the conversion of pressure. The following is a detailed analysis of the precision gear pump hydraulic system:

1. Working principle of gear pump

The gear pump is a rotary pump that relies on the change and movement of the working volume formed between the pump cylinder and the meshing gear to deliver liquid or increase pressure. Its working principle is mainly based on the meshing and rotation of gears. When the gears rotate, the tooth valley (between teeth) between the gears forms a sealed working chamber. As the gears mesh and rotate, the volume of the sealed working chamber changes, thereby realizing the suction and discharge of liquid.

2. Characteristics of precision gear pumps

Precision gear pumps have higher precision and performance requirements than ordinary gear pumps. Its main features include:

High precision: The precision gear pump has higher gear processing accuracy and more precise tooth shape, which ensures higher volumetric efficiency and pressure stability.

High pressure: Precision gear pumps can withstand higher working pressures and are suitable for high-pressure hydraulic systems.

Low noise: Due to the precise meshing of gears and the use of high-quality materials, precision gear pumps have lower noise.

High reliability: The structural design of precision gear pumps is more reasonable, and the material selection is better, so it has higher reliability and service life.

3. Application of precision gear pump hydraulic system

Precision gear pump hydraulic system is widely used in various industrial fields, such as machine tools, oil extraction, construction, agriculture, etc. In these fields, precision gear pump hydraulic system is used for liquid transportation, circulation, pressurization and other processes, meeting the needs of various complex working conditions.

4. Performance parameters and selection

When selecting a precision gear pump, it is necessary to comprehensively consider its performance parameters, including flow, pressure, speed and efficiency. These parameters directly affect the working performance and application range of the gear pump.

Flow rate: The flow rate represents the volume of liquid delivered by the gear pump per minute. When selecting, the appropriate flow rate needs to be determined according to the actual working needs.

Pressure: Pressure refers to the maximum pressure that the gear pump can withstand. When selecting, the specific working conditions of the system, the required pressure level and the pressure resistance of the material should be considered.

Speed: The speed directly affects the output power and delivery efficiency of the pump. When selecting, it is necessary to comprehensively consider factors such as system requirements, energy supply and cost-effectiveness.

Efficiency: Efficiency is an important indicator for measuring the performance of a gear pump. High efficiency means less energy loss, which can effectively improve the system's working efficiency and energy-saving performance.

In summary, the precision gear pump hydraulic system is an important component of the hydraulic system, with the characteristics of high precision, high pressure, low noise and high reliability. When selecting and using it, it is necessary to comprehensively consider its performance parameters and applicable scope to meet the needs of various complex working conditions.